TM 5-3895-373-34

D.

REPAIR - Continued.

e.

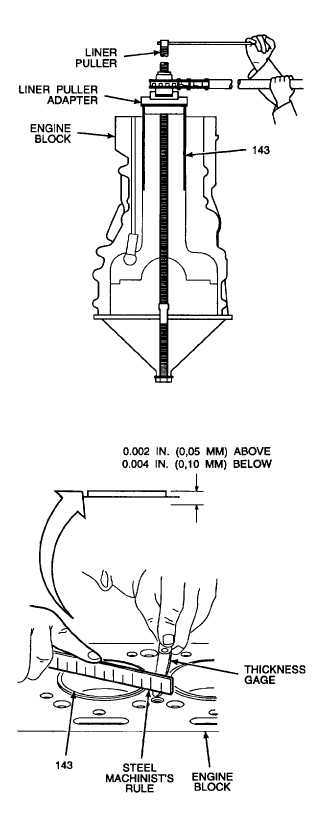

Use a liner puller adapter with liner puller to

press cylinder sleeves into engine block,

until approximately 2.0 in. (50,8 mm) of

cylinder sleeve protrudes from engine block

top face.

f.

Apply sealing compound to top 1.0 in. (25,4

mm) of outer surface of cylinder sleeve and

under flange. Also apply sealing compound

to bottom of flange recess in engine block.

g.

Press cylinder sleeve (143) into engine

block until nearly flush with engine block top

face.

h.

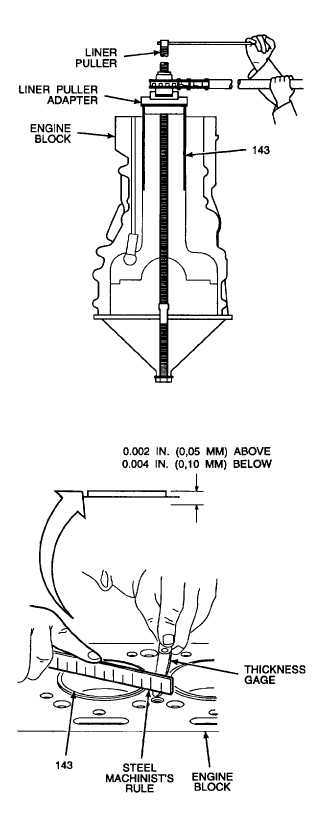

Place a steel machinist’s rule across top of

cylinder sleeve (143).

i.

Slide a thickness gage into gap between

steel machinist’s rule and top of engine

block.

j.

Measure

protrusion

of

cylinder

sleeve

above top face of engine block. Cylinder

sleeve protrusion must be from 0.002 in.

(0,05 mm) above engine block top face to

0.004 in. (0,10 mm) below engine block top

face.

GO TO NEXT PAGE

2-189