TM 5-3895-373-34

D.

REPAIR - Continued.

f.

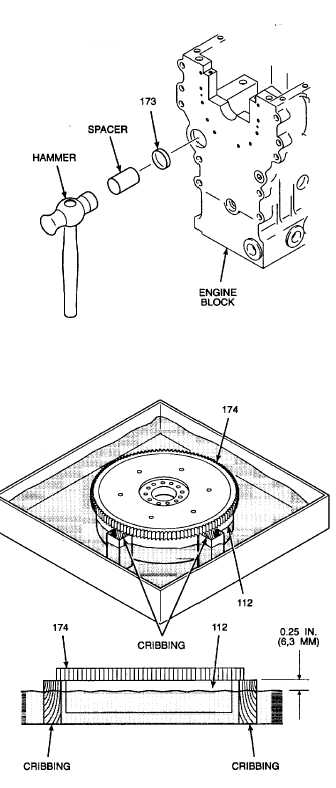

Use a hammer and a spacer from universal

puller kit to tap expansion plug (173) into

engine block until flush with machined face

of engine block.

5.

REPAIR FLYWHEEL BY REPLACEMENT OF

SPUR GEAR.

a.

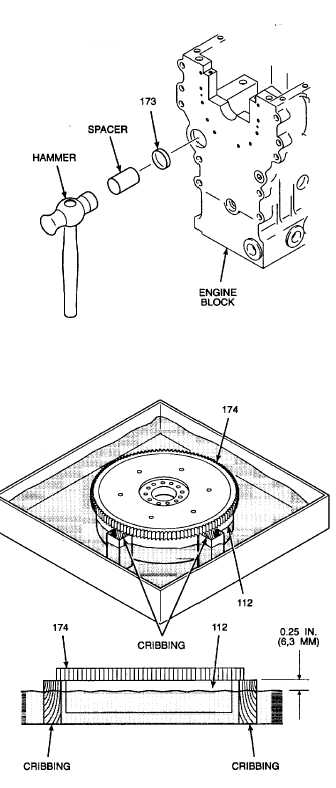

With spur gear (174) facing up, place

flywheel (112) in clean, cold water about

60°F (21°C), supported by four pieces of

cribbing under spur gear (174). Bottom of

spur gear must be approximately 0.25 in.

(6,3 mm) above water surface.

Use caution when handling hot spur

gear. Severe burns may result if

caution is not used when handling

heated spur gear. Use a suitable tool

and wear insulated gloves when

handling heated spur gear.

b.

Use a gasoline blowtorch to heat spur gear

(174) evenly around circumference until

flywheel (112) drops away from spur gear.

c.

After allowing flywheel to cool, remove

flywheel (112) from water.

d.

Heat new spur gear (174) to approximately

475°F (246°C).

GO TO NEXT PAGE

2-191