TM 5-3895-373-34

1.21

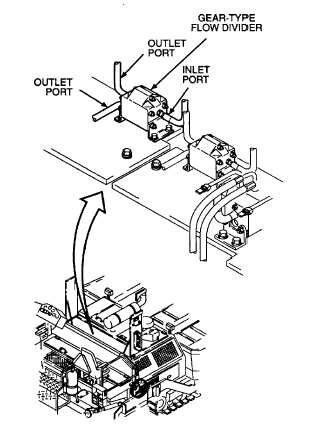

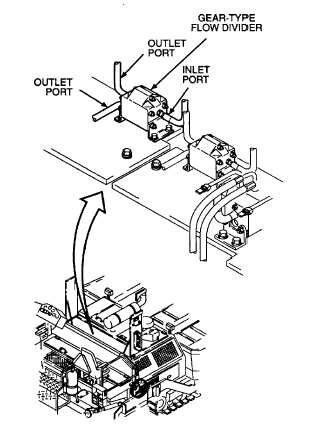

50/50 FLOW DIVIDER.

50/50 flow dividers split the flow from a single input into

two equal output flows. There are two types of 50/50

flow divider used in the paving machine.

a.

Gear-type flow dividers. Gear-type flow

dividers are mounted on brackets that attach to the valve

panel. There are three gear-type flow dividers in the

paving machine. One flow divider splits the input flow to

the two auger/conveyor systems. A second flow divider

splits flow between the stack valve and the tow point

cylinders. Each displaces 0.32 cubic inches (5,24 ml)

per side. A third flow divider splits flow between two tow

point cylinder circuits and has a displacement of 0.109

cubic inches (1,786 ml) per side. Hydraulic oil enters

the inlet port and passes through two sets of meshing,

double-gear assemblies. Each double gear assembly

consists of two gears joined by a single shaft. As oil

passes over the gears, they turn and engage an opposite

set of gears. Hydraulic oil flow is equally regulated by

the inertia created by the meshing sets of gears.

Hydraulic oil output is equal from both outlet ports.

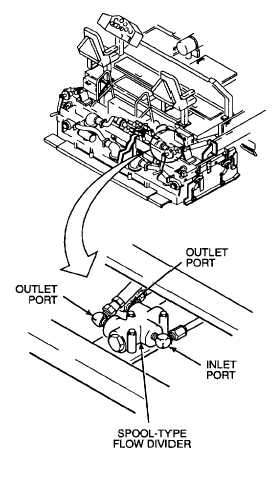

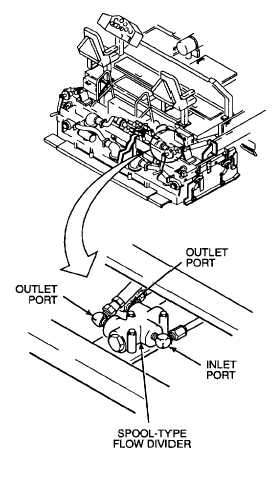

b.

Spool-type flow dividers. Spool-type flow

dividers contain a pressure-compensated spool that

balances oil flow. There is one spool-type flow divider

located in the screed vibrator assembly. The flow divider

input is channeled through a bored spool. The spool

centers and self-adjusts as the oil passes through. This

compensates for unequal hydraulic oil draw from each of

the components and ensures an equal and constant

output flow.

1-12