TM 5-3895-373-34

1.25

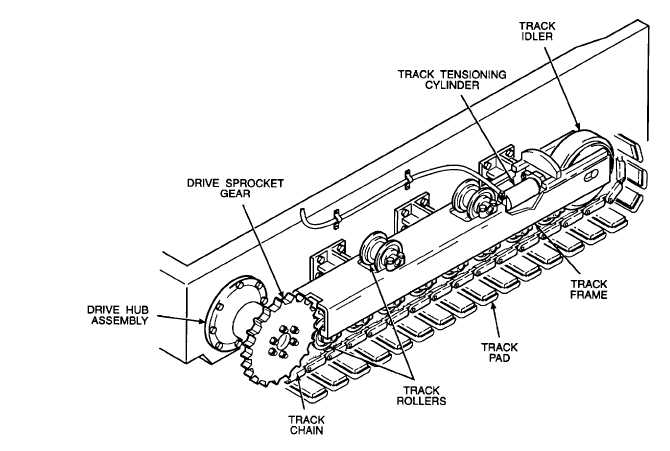

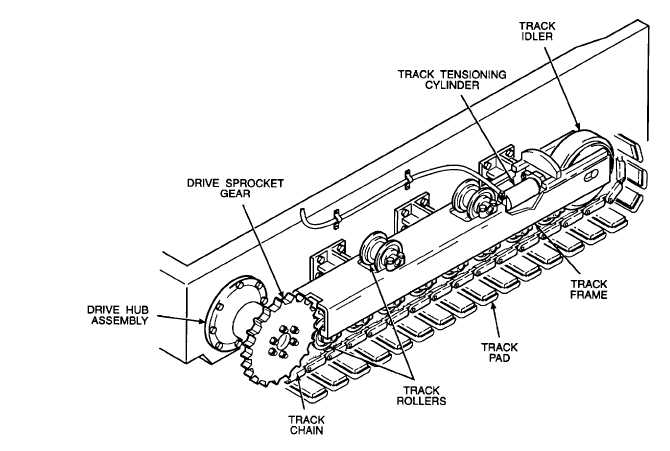

TRACK SUSPENSION ASSEMBLY.

The track suspension assembly assists in supporting,

propelling, and steering the paving machine.

a.

Drive Hub Assembly: The drive hub

assembly is bolted to the main frame of the paving

machine. The drive hub transfers energy from the

hydraulic propulsion system to the drive sprocket gear.

b.

Drive Sprocket Gear: The drive sprocket

gear transfers drive power to the track chain.

c.

Track Tensioning Cylinder: The track

tensioning cylinder receives a 900 psi (6205 kPa)

hydraulic charge after engine startup and applies this

constant pressure to the track idler to establish and

maintain proper track tension.

d.

Track Idler: The track idler is located at the

forward end of the track frame and has a fixed amount of

travel to compensate for changes in track tension. From

its forward location, the track idler supports the front end

track loop and maintains proper track tension by sliding

forward and back in conjunction with the track tensioning

cylinder. The track idler roller also helps reduce track

rolling resistance.

e.

Track Frame: The track frame is bolted

directly to the machine frame. It provides support to two

top track rollers and eight lower rollers. The unit houses

the track tensioning cylinder and track idler.

f.

Track: The track consists of a series of

track pads bolted to a track chain. The track chain,

engaged with the rotating drive sprocket gear, propels

the paving machine along the ground.

g.

Track Rollers: Track rollers provide support

for the track chain and aid in its alignment. The rollers

also create a lower demand for drive power by reducing

track rolling resistance.

1-15