TM 5-3895-373-34

1.22

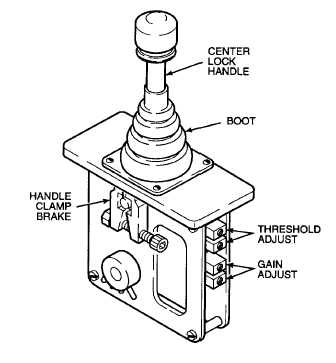

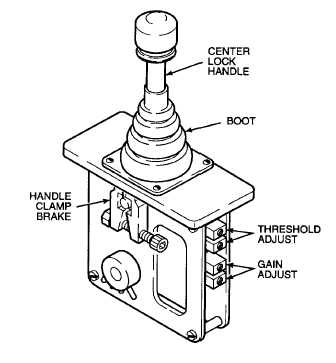

CONTROL HANDLES.

Two control handles (joysticks) are located on the

operator console. Each control handle is a friction held,

bi-directional unit with adjustable drag. A clamp-type

brake holds each handle at set position. Each handle

has a throw of 30° on either side of center. Control

handles operate on a 12 volt DC current. A printed

circuit board on each handle subassembly converts the

12 volts DC to a 96 mA signal to power the coils on

pump pilot control valves. Full current output, with the

control handles at 30°, is a maximum of 2 amps into a 5

ohm load. Step current (96 mA) is a maximum of 50% of

full current output. The current can be adjusted through

the use of threshold and gain controls. Control handles

govern startup functions, travel speed variations, brake

release (when engaging paving machine travel), and

automatic screed vibration operation. The paving

machine engine will not start unless both control handles

are centered. Each control handle operates its

respective track. When paving with screed vibration in

automatic, screed vibration is halted when either control

handle is centered. Screed vibration resumes when both

handles are moved out of the center position.

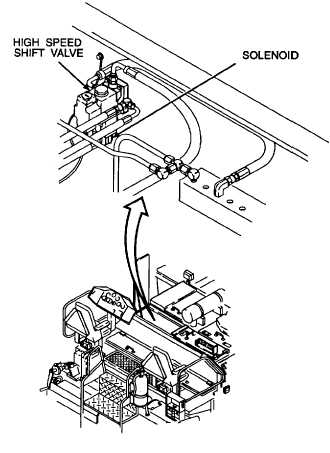

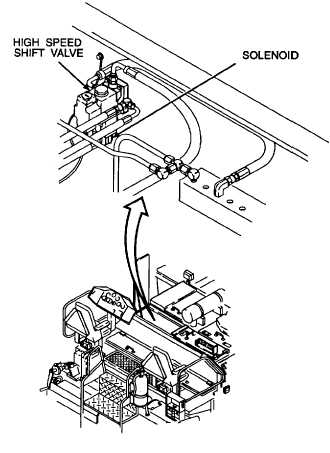

1.23

HIGH SPEED SHIFT VALVE.

The high speed shift valve is a 12 volt DC, solenoid

activated, two-position, four-way valve that enables the

paving machine to move at two separate speed ranges.

The high speed is used for traveling, and the low speed

is used for paving. The solenoid is wet-operated for low

impact and smooth operation. The high speed shift

valve controls oil flow to the hydraulic motor control

pistons. The oil flow determines the control piston angle,

which determines drive speed. The internal charge

circuit of the left propulsion pump provides the required

flow of hydraulic oil to the high speed shift valve.

1-13