TM 5-3895-373-34

1.17

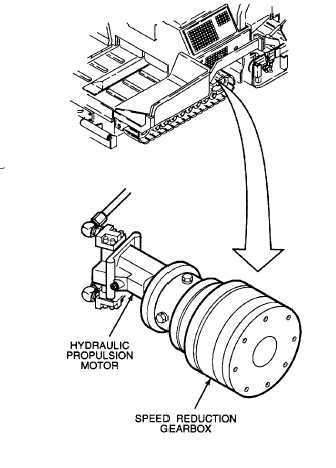

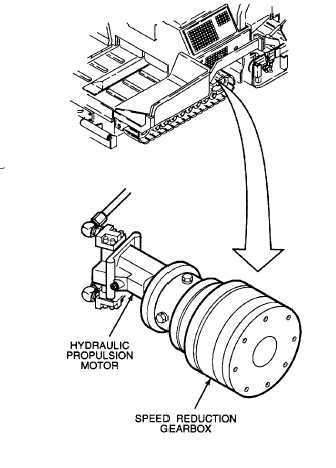

HYDRAULIC PROPULSION MOTOR.

The paving machine uses two hydraulic propulsion

motors. A separate motor is used for the right and left

side. The left motor is powered by the left hydraulic

propulsion pump and the right motor is powered by the

right

hydraulic

propulsion

pump.

The

following

description applies to either motor.

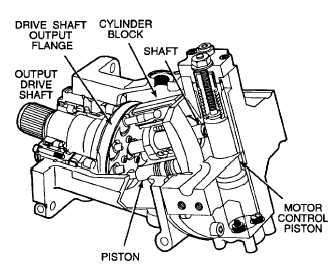

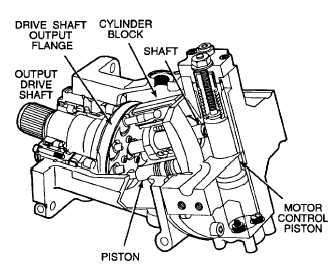

The hydraulic propulsion motor is a bent axis, piston

type, high torque, variable speed, bi-directional motor. It

has a maximum displacement of 3.05 cubic inches

(49,98 ml) and a minimum displacement of 1.13 cubic

inches (18,52 ml) per revolution. Operating pressure is

5000 psi (34 475 kPa). The charge pump in the left

propulsion pump provides flow and pressure, 350 psi

(2413 kPa), to the high speed shift valve. The high

speed shift valve controls the paving speed and travel

speed of the propulsion motors.

Oil flow through the high speed shift valve positions the

motor control piston. The control piston is linked by a

shaft to the cylinder block and sets the angle at which the

cylinder block turns. The greater the angle of the

cylinder block, the slower the motor turns; the lesser the

angle, the greater the speed output.

The cylinder block contains seven pistons. Each piston

applies force, through a connecting rod, to the drive shaft

output flange causing the output flange to rotate. High

pressure oil forces the pistons out, which causes a

downward rotation on the output flange. Rotation of the

output flange produces a rotation of the output drive

shaft. Meanwhile, pistons on the opposite side of the

flange are retracting, forcing the oil out at low pressure,

back to the reservoir.

The propulsion motors are cooled by controlled fluid

leakage. A three-way, pressure driven, flushing valve

allows heated hydraulic oil to exit the system and return

to the hydraulic reservoir.

1.18

SPEED REDUCTION GEARBOX.

The speed reduction gearbox links the hydraulic

propulsion motors to the track hubs and drive sprocket

gears. There is one reduction gearbox for each track.

The reduction gearbox is a triple-stage unit with a

reduction ratio of 65:6:1 and a continuous operating

torque of 4700 lb-ft (6372 N•m).

1-9