TM 5-3895-373-34

E.

ASSEMBLE - Continued.

Compressed air used for cleaning purposes

will not exceed 30 psi (207 kPa). Use only

with effective chip guarding and personal

protective equipment (goggles/face shield

and

gloves).

Failure

to

take

proper

precautions may result in severe injury or

loss of vision.

b.

Use

30

psi

(207

kPa)

maximum

compressed air to blow any foreign material

from seal grooves, inside of cylinder tube,

and threaded surfaces.

c.

Dry parts with a clean, lint-free cloth. Set

dry parts on clean surface. Place a clean,

lint-free cloth into open end of cylinder tube

to prevent contamination.

2.

INSTALL PACKINGS AND SEALS.

Hydraulic oil can be moderately flammable

and can be an irritant to the skin, eyes, and

respiratory

system.

Avoid

prolonged

exposure. Eye protection and rubber gloves

must be worn when working with hydraulic

oil.

a.

Lubricate all internal components with clean

hydraulic oil.

New seals and preformed packings are

distorted during installation. Use care during

installation to prevent damage to seals and

preformed packings. Bypass leakage can

result

from

careless

packing

or

seal

installation.

b.

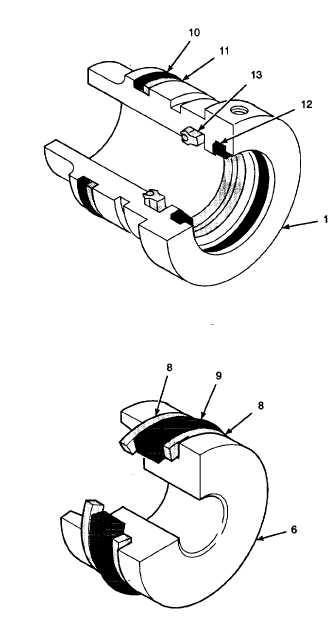

Pinch sides of compression cup (13)

together to form a C-shape. Insert one side

of compression cup in mating seal groove

of cylinder head (1), and let opposite side

snap into place.

c.

Install ring wiper (12) into cylinder head (1)

using same method used in step b.

.

d.

Install packing retainer (11) and o-ring (10)

in mating groove of cylinder head (1).

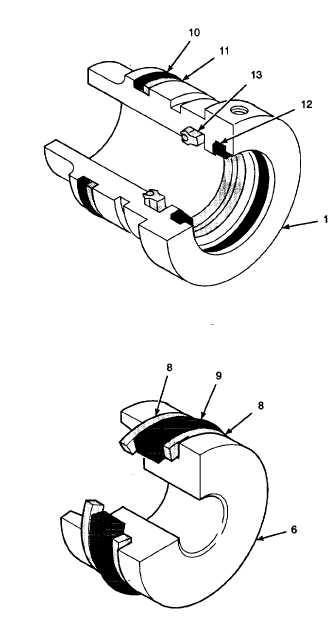

e.

Install packing retainers (8) and seal (9) on

piston (6). Make sure seal is seated

between installed packing retainers.

GO TO NEXT PAGE

2-1017