TM 5-3895-373-34

C.

INSPECT - Continued.

4.

INSPECT PISTON.

a.

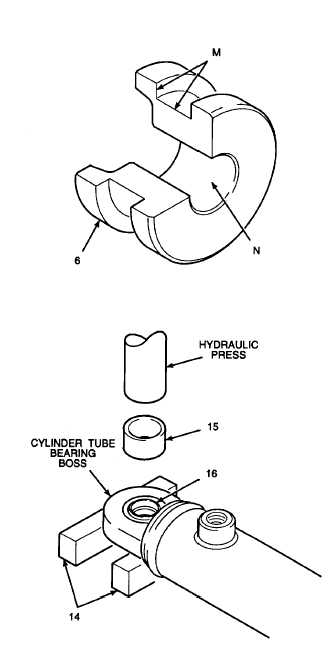

Inspect piston (6) packing groove M, and

bore surface N. Check for any sharp edges

or nicks that may damage packings or

seals. Remove sharp edges and nicks with

crocus cloth.

b.

Replace piston if scratches, pits, sharp

edges, or nicks cannot be polished out, or if

surface defect exceeds 0.5 in. (12,7 mm) in

length.

D.

REPAIR.

1.

PRESS OUT SPHERICAL BEARING.

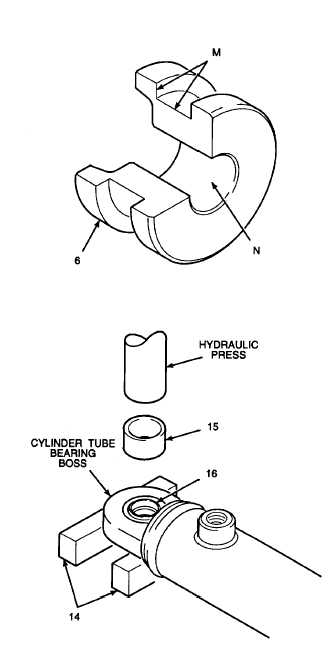

Place

support

blocks

close

to

bushing seat when pressing out

spherical bearing. Failure to place

support blocks correctly may lead to

warping of the cylinder tube bearing

boss.

a.

Place cylinder end on hand operated arbor

press. Make sure support blocks (14) are

placed under the cylinder tube base.

b.

Use hydraulic press frame and hollow

spacer (15) from universal puller kit to

remove spherical bearing (16) from bore.

2.

PRESS IN REPLACEMENT BEARING.

Place

support

blocks

close

to

bushing

seat

when

pressing

in

spherical bearing. Failure to place

support blocks correctly may lead to

warping of the cylinder tube bearing

boss.

a.

Place cylinder base end on hand operated

arbor press. Use press fixture support

blocks (14) to support bearing boss.

GO TO NEXT PAGE

2-1015