TM 5-3895-373-34

2.70

REPAIR SCREED LIFT CYLINDER - Continued.

C.

INSPECT- Continued.

2.

INSPECT PISTON ROD.

a.

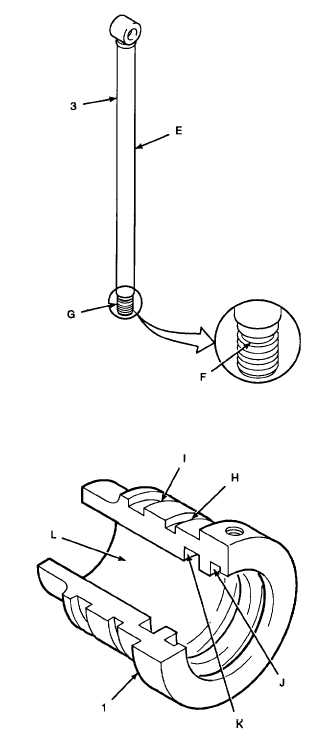

Run your finger along piston rod (3),

surface E. Feel for any scratches or sharp

edges

that

may

damage

preformed

packings and seals. Inspect surface of

piston rod for scratches, pits, or wear that

expose base metal through chrome plating.

b.

Remove sharp edges of nicks or scratches

using crocus cloth.

c.

Replace piston rod if scratches or pits can

not be polished out, if scratch exceeds 0.5

in. (12,7 mm) in length, or if base metal is

exposed through chrome plating.

d.

Visually inspect packing groove F and feel

for nicks and sharp edges. Remove sharp

edges using crocus cloth. If packing

groove edge is cracked or chipped replace

piston rod.

e.

Inspect threads G. If threads are distorted,

replace piston rod.

3.

INSPECT CYLINDER HEAD.

a.

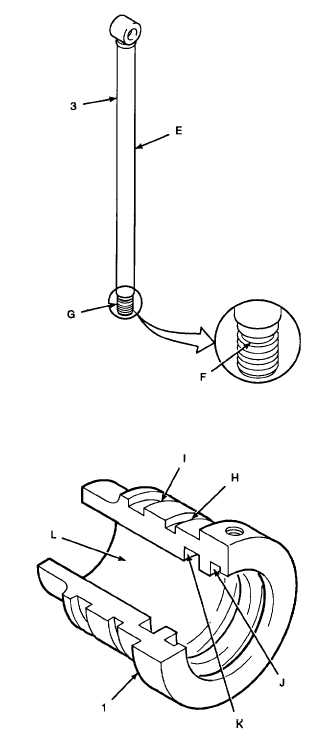

Visually inspect cylinder head (1) retaining

ring groove H, preformed packing groove I,

ring wiper groove J, and compression cup

groove K. Check for any raised edges, or

nicks that may damage packings or seals.

Remove raised edges and nicks with

crocus cloth.

b.

Replace cylinder head if raised edges or

nicks cannot be polished out.

c.

Inspect bore surface L, for nicks, pits, or

scratches. Remove nicks, pits, or scratches

of less than 0.5 in. (12,7 mm) in length with

crocus cloth.

d.

Replace cylinder head if nicks, pits, or

scratches cannot be polished out of bore

surface L.

GO TO NEXT PAGE .

2-1014