TM 5-3895-373-20

14.3.

REPLACE/REPAIR BURNER AND FUEL SPRAY

B.

REPAIR - Continued.

2.

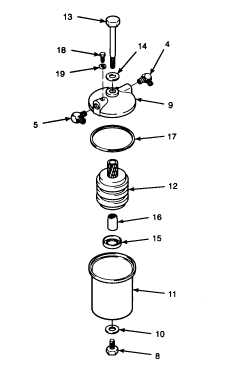

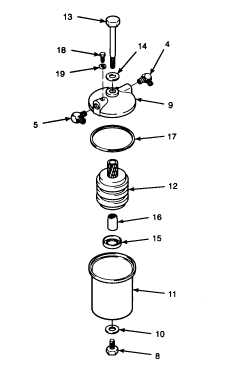

ASSEMBLE FUEL FILTER COMPONENTS.

a.

Seat filter element (12) on center spud (16)

and seal (15) and place in filter bowl (11).

Secure filter element in place with gasket

(10) and spud bolt (8). Tighten spud bolt as

tight as possible with fingers.

WARNING

Fuel is very flammable and can

explode easily. To avoid serious

injury or death:

Always wear safety glasses/goggles

at all times.

Keep fuel away from open flame or

spark (ignition source).

Keep at least a B-C fire extinguisher

within easy reach when working with

fuel or on a fuel system.

Post signs that read "NO SMOKING

WITHIN 50 FEET" when working with

open fuel lines or fuel tanks.

b.

Coat filter head gasket (17) with clean fuel

and place on filter bowl (11).

c.

Squarely seat filter bowl (11) onto filter head

(9). Secure with gasket (14) and center bolt

(13).

CAUTION

Ensure that center spud (16) is seated

in the bottom of filter bowl (11) or

filter element (12) may be smashed.

d.

Hold filter and tighten spud bolt (8) then

tighten center bolt (13).

e.

Install vent gasket (19) and vent screw (18)

and tighten vent screw.

f.

Use cleaning cloth to wipe residue from

threads of elbows (4 and 5).

WARNING

Pipe sealant can cause eye damage

or skin irritation. Wash after skin

contact. Wear safety goggles/glasses

when using. Avoid contact with eyes

or skin. If sealant contacts eyes,

flush

eyes

with

water

and

get

immediate medical attention.

g.

Apply a light coating of pipe sealant to pipe

threads of elbows (4 and 5). Ensure pipe

sealant is used sparingly so as not to clog

fuel hoses or other fuel components.

h.

Install pipe thread side of elbows (4 and 5)

into filter head (9). Tighten elbows so that

they are both pointed in the direction

shown. Refer to illustration.

GO TO NEXT PAGE

14-12