TM 5-3895-373-20

4.5. REPAIR FUEL TANK - Continued.

B. INSTALL.

WARNING

Fuel is very flammable and can

explode easily. To avoid serious

injury or death:

Always wear safety glasses/goggles

at all times.

Keep fuel away from open flame or

any spark (ignition source).

Keep at least a B-C fire extinguisher

within easy reach when working with

fuel or on a fuel system.

Post signs that read "NO SMOKING

WITHIN 50 FEET" when working with

open fuel lines or fuel tanks.

1.

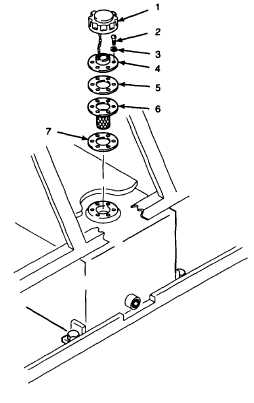

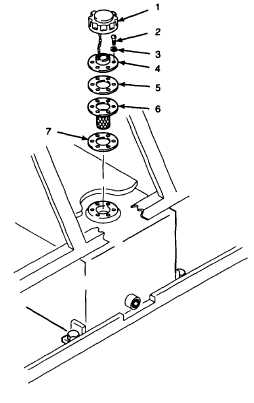

ASSEMBLE BREATHER AND FILLER NECK.

a.

Align mounting holes on gasket (7) with

the mounting holes on fuel tank and place

the gasket onto the fuel tank.

b.

Align mounting holes of fuel strainer (6)

with mounting holes on the fuel tank and

place the fuel strainer onto gasket (7).

c.

Align mounting holes of gasket (5) with

mounting holes on the fuel tank and place

the gasket onto fuel strainer (6).

d.

Align mounting holes of filler neck (4) with

the mounting holes on fuel tank and place

the filler neck onto gasket (5)

2.

INSTALL FILLER/BREATHER ASSEMBLY.

CAUTION

Before installing machine screws,

visually inspect that all mounting

holes

are

aligned.

Gasket

misalignment

can

cause

gasket

damage and possible leakage.

a.

Visually inspect that mounting holes in

filler neck (4), gaskets (5 and 7), and fuel

strainer (6) are aligned with mounting

holes in fuel tank.

CAUTION

Do not use metric screws that come

with new fuel tank filler assembly.

Obtain correct machine screws from

the supply system.

b.

Install

machine

screws

(2)

and

lockwashers (3).

c.

Install fuel tank cap (1).

NOTE

FOLLOW-ON-TASKS: Install left access cover per TM 5-3895-373-10.

Close left access door per TM 5-3895-373-10.

END OF TASK

4-30