TM 5-3895-373-20

1.14.

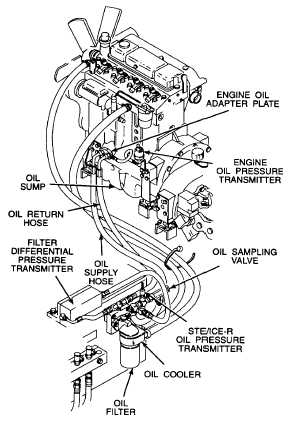

ENGINE LUBRICATION SYSTEM.

The main components of the engine lubrication system

include the oil pump, oil cooler, oil filter, and oil pressure

sensing devices. The lubrication of the engine is of the

force feed type. The oil is circulated by a gear type

pump internal to the engine balancer unit mounted to the

bottom of the engine block inside the oil sump. The oil is

drawn through a sump strainer tube to the pump. Oil is

then pumped to the engine internal oil passages.

The oil pump provides a high pressure oil flow to a

through port on the engine oil adapter plate. A supply

hose connected to the port routes the high pressure oil to

the oil cooler and filter. A pressure tap off the high

pressure port supplies oil to an engine oil pressure

transmitter. The resistance of the transmitter changes

based on the sensed oil pressure. A pressure gauge on

the operator gauge panel displays the oil pressure.

Inside the oil cooler high pressure oil flows through

cooling vanes and into the oil filter. Engine coolant

circulates through the oil cooler, removing excess heat

from the engine oil. A replaceable filter element in the oil

filter removes particulates from the engine oil. Filtered

oil is routed back to the return port on the engine oil

adapter plate. Oil returned from cooling and filtration

flows into the engine oil gallery inside the engine block.

The oil is then routed throughout the engine.

An oil sampling valve and STE/ICER oil pressure

transmitter are located at the input to the oil cooler and

filter. Oil filter input and output pressures are monitored

by a differential pressure transmitter. When filter

contamination inhibits oil flow, the transmitter turns on.

The transmitter condition can be detected at the DCA

connector using STE/ICER Test Nos. 35 and 36.

1-17