TM 5-3895-373-20

1.15.2.

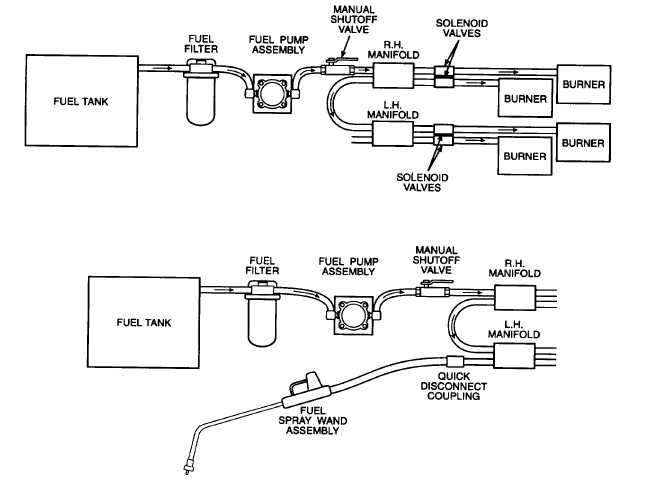

Screed Burner Fuel System. The

screed burner fuel system consists of fuel tank, fuel filter,

fuel

pump

assembly,

manual

shutoff

valve,

two

manifolds, four solenoid valves, and four screed burners.

The fuel filter has one input and one output. The filter

removes impurities from the fuel supply by passing the

fuel through a filter. From the filter, the fuel is sent to a

fuel pump assembly.

The fuel pump assembly consists of an electric motor

shaft coupled to a single stage pump. The motor is

controlled from the left screed control panel. The pump

has a continuous output of 7 gph (26 V/hr).

From the fuel pump, fuel is supplied to a manifold

through a manual shutoff valve.

The right hand manifold is a divider with one input and

three outputs. One output is the input to the left hand

manifold. The remaining two outputs are to the screed

burners on the right side of the screed. The left hand

manifold has one output used

by the spray wand assembly and two outputs for the

screed burners on the left side of the screed.

Electrical solenoid valves control the flow of fuel from the

manifolds to the burners. These valves are controlled by

separate switches on the screed control panels. This

allows for independent burner operation.

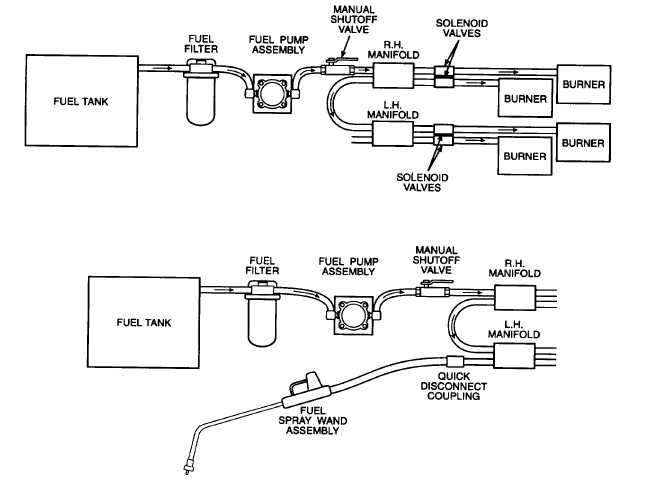

1.15.3. Washdown Spray Assembly Fuel System.

The washdown spray assembly fuel system consists of

fuel tank, fuel filter, fuel pump assembly, manual shutoff

valve, two manifolds, four solenoid valves, and spray

wand assembly. The fuel pump that draws fuel to the

screed burners also provides fuel for the spray

washdown system.

The spray wand assembly consists of a 10 ft (3 m) quick

disconnect hose, fitting, and a triggertype control wand.

The spray wand assembly is primarily used to spray fuel

on components that are directly exposed to paving

material. This prevents paving material from sticking,

and allows the material to be removed from machine

components by scraping or other mechanical means.

1-19