TM 5-3895-373-20

1.15.

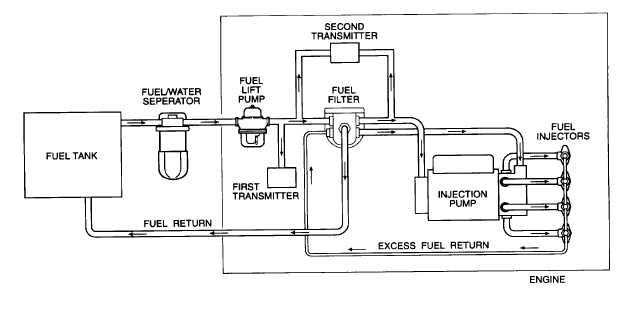

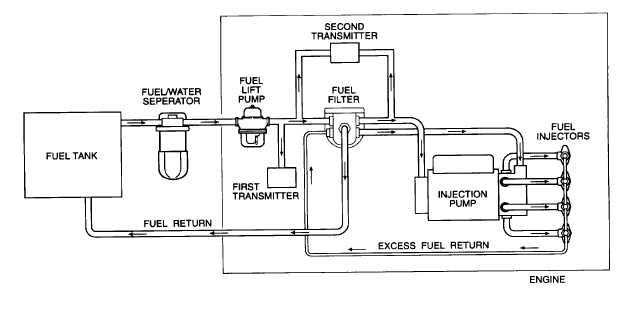

FUEL SYSTEM.

1.15.1. Engine Combustion Fuel System.

The engine combustion fuel system consists of a

fuel tank, fuel/water separator, fuel lift pump, fuel filter,

two test transmitters, fuel injection pump, and engine fuel

injectors.

The fuel tank is a 28 gal (106 Q) fuel storage source for

the paving machine. The fuel tank fill contains a strainer

for filtering out large particles. An electrical fuel level

transmitter controls the fuel gauge on the operator

control panel. The fuel tank outputs to a fuel/water

separator.

A diaphragm-type fuel lift pump draws fuel from the fuel

tank through a fuel/water separator, forcing the fuel on to

the test transmitters and the fuel filter. The fuel pump is

driven by an eccentric on the engine cam. A lever on the

fuel pump can be used to manually feed fuel through the

system.

The fuel pump output is sent to the first transmitter which

measures fuel pressure for use by the STE/ICER Test

Set, Test No. 24. The second transmitter measures fuel

pressure into the fuel filter and compares it with the fuel

pressure out of the fuel filter for STE/ICER Test No. 26.

The fuel filter has two inputs that remove impurities from

the fuel supply through a filter. One input is from the fuel

lift pump and the second input is from the overflow of the

injectors on the engine. Two outputs from the fuel filter

feed the injection pump. A third output is a return to the

fuel tank for excess fuel.

Fuel is forced from the fuel filter to a fuel injection pump.

This pump uses both a high pressure and a low pressure

input. The pump is driven by engine timing gears to

provide fuel to each cylinder injector. Excess fuel

supplied to the injectors is returned to the fuel filter.

1-18