TM 5-3895-373-20

B.

INSTALL.

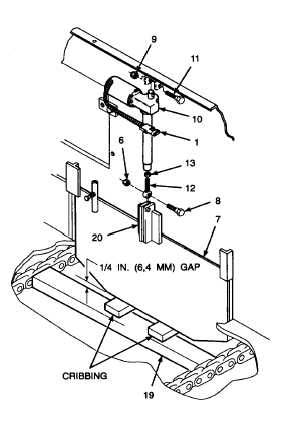

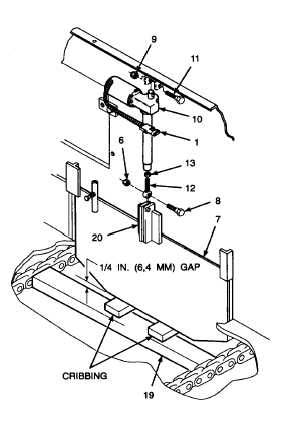

1.

INSTALL FLOW GATE AND LINEAR

ACTUATOR.

a.

Position flow gate (7) in slide brackets and

lower to bottom of slide, holding the lower edge

of the flow gate as level as possible. If the flow

gate does not touch the conveyor drag plate

guard, ensure 1/4 in. (6,4 mm) gap is held

between lower edge of flow gate and conveyor

chain drag bars.

b.

Use cribbing to prop up flow gate (7) 1/4 in.

(6,4 mm) above top edge of drag bars (19), if

not resting on the conveyor drag plate guard.

c.

Install linear actuator (10) and secure with hex

head cap screw (11) and self-locking hex nut

(9).

d.

Apply

electrical

insulating

compound

to

electrical connector (1) and reconnect to engine

harness.

e.

Extend linear actuator to full length per TM 5-

3595373-10.

f.

Install jam nut (13) on rod end (12). Screw rod

end into bottom of linear actuator a minimum of

four threads. If rod end is lower than mounting

holes in flow gate left bracket (20), screw rod

end into bottom of linear actuator until rod end

and mounting holes in flow gate left bracket

align. If rod end is higher than mounting holes

in flow gate left bracket (20), raise flow gate to

align mounting bracket with rod end. Install hex

head cap screw (8) and tighten jam nut.

g.

Install and tighten self-locking hex nut (6).

WARNING

Adhesive

is

TOXIC

and

extremely

flammable. Keep away from heat, sparks,

and open flames. Use only in well

ventilated areas. Do not breathe vapors

or swallow and avoid contact with eyes

and skin. Failure to do so may result in

injury or death to personnel.

If personnel become dizzy while using

adhesive, immediately get fresh air and

medical attention. If personnel swallow

adhesive, do not induce vomiting. Get

immediate medical attention. If adhesive

contacts eyes, flush eyes with water for 15

minutes and get immediate medical

attention. If adhesive contacts skin, wash

thoroughly with soap and water.

h.

Apply adhesive to the back of any sound foam

that was loosened and place the sound foam

back into position.

GO TO NEXT PAGE

15-75