TM 5-3895-373-10

SECTION III. PRINCIPLES OF OPERATION

1.12

PAVING MACHINE.

The paving machine consists of the tractor and screed.

It is normally manned with one paving machine operator

and two screed crew members. The tractor unit pushes

a haul truck while the haul truck unloads paving material

into the tractor hopper. The twin dual slat conveyor

system on the tractor unit carries the paving material

from the hopper to the augers. Two electrically-

controlled flow gates, mounted behind the hopper,

regulate the amount of material fed to the augers at the

back of the tractor. The augers spread the paving

material evenly along the length of the leading edge of

the screed. As the tractor unit moves forward, it tows the

screed over the paving material. Burners on the screed

heat the screed plate and maintain its temperature equal

to that of the paving material to prevent sticking. The

screed is equipped with a vibrating screed plate, which

provides a high degree of compaction to the paving

material passing underneath it.

Both the tractor and screed units are equipped with

controls that impact the paving operation. The paving

machine operator can operate virtually all machine

functions. The screed crew control boxes contain

controls limited to paving functions.

1.13

TRACTOR.

The tractor is powered by a Perkins T4.236 turbocharged

diesel engine coupled to a pump drive gearbox that

provides power to five hydraulic pumps. Two hydraulic

propulsion pumps are attached to the gearbox and

provide hydraulic oil pressure to drive the propulsion

motors mounted on the track frame. Two hydraulic

auxiliary pumps and a hydraulic auxiliary vibration pump

are attached in tandem to the propulsion pumps. These

pumps provide hydraulic oil power to auger/conveyor

motors, vibration motors, and all hydraulic

cylinder functions on the paving machine. Additional

components such as push rollers, hopper wings, and

flow gates are discussed in the following paragraphs.

1.13.1

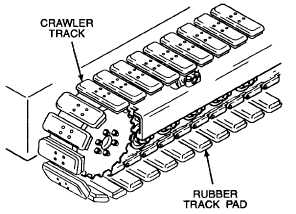

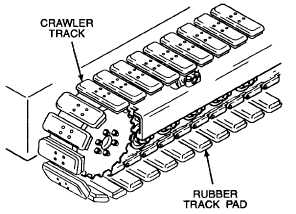

Track Drive. The paving machine is mounted on

steel crawler tracks equipped with rubber track pads

mounted on steel track pad plates. The hydraulically-

powered track drive evenly distributes and supports the

weight of the paving machine for greater stability. The

tracks operate individually in the forward and reverse

directions at variable speeds. The tracks can be

counter-rotated for quick turning maneuvers.

1.13.2

Push Rollers. The push rollers are located on

the front of the paving machine. The push rollers contact

the tires of the haul truck and allow the tractor to push it

while receiving paving material. To compensate for

misalignment between tractor and haul truck, the push

rollers are mounted on a pivoting bumper.

1-7