TM 5-3895-373-10

1.13.3

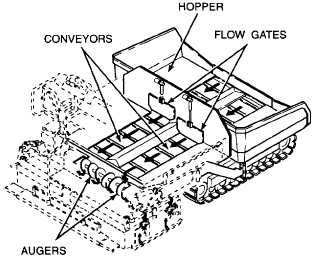

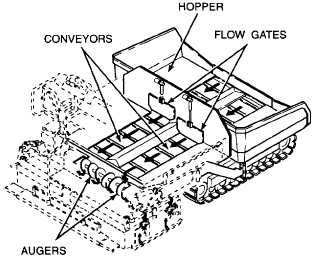

Hopper. The paving machine hopper receives

and temporarily holds the paving material from the haul

truck. The hopper wings move inward to facilitate

dumping paving material onto the conveyors and

outward to receive paving materials. Heavy rubber

flashing mounted on the hopper reduces the amount of

paving material that could spill from the hopper. The

paving machine operator controls the hopper wing

movement from the operator control console.

1.13.4

Auger/Conveyor System. The conveyors move

paving material from the hopper to the augers located on

the back of the tractor. The right and left auger/conveyor

systems operate independently of each other. The

paving machine operator selects manual or automatic

control of each separate auger/conveyor system. The

augers move the paving material outward from the

conveyors, distributing it evenly to the screed. Reversing

direction of the conveyors empties the hopper toward the

front of the paving machine.

Operation of the left and right auger/conveyor systems

can also be controlled from the screed crew control

boxes.

The

left

control

box

controls

the

left

auger/conveyor system, and the right control box

controls the right auger/conveyor system.

1.13.5

Flow Gates. Two flow gates are mounted at the

back of the hopper, one on either side. Each can be

independently raised or lowered from the operator

control console. The position of the flow gates controls

flow of the paving material to the augers.

Operation of the left and right flow gates can also be

controlled from the left and right screed crew control

boxes. The left control box can control only the left flow

gate, and the right control box can control only the right

flow gate.

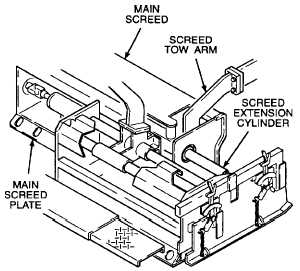

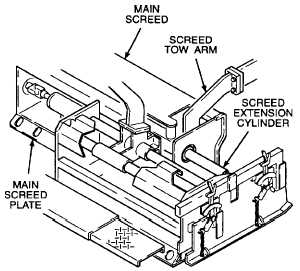

1.14

SCREED.

The screed is towed by and receives paving material

from the tractor. As the tractor moves forward, the

screed is towed over the paving material. The screed

provides the initial compaction through vibration and lays

paving material to the desired thickness and finish.

1.14.1

Main Screed. The main screed provides the

structural rigidity for the screed and is attached to the

tractor by two screed tow arms. The main screed plate,

bolted to the bottom of the main screed, rides on top of

the paving mat and creates a smooth finish. The weight

and vibration of the main screed provides initial

compaction of the mat. Screed extension cylinders

mounted inside the main screed extend and retract the

extension screeds. The paving machine operator

controls the operation of the main screed from the

operator control console.

1-8