(8) Toggle Switches and Electrical Connections - A common cause of hydraulic system problems is electrical

failure due to a broken wire, loose connection, or an inoperative toggle switch. When a single hydraulic function fails to

occur while another works normally it is wise to check the wiring and switch details first before performing more complex

troubleshooting work.

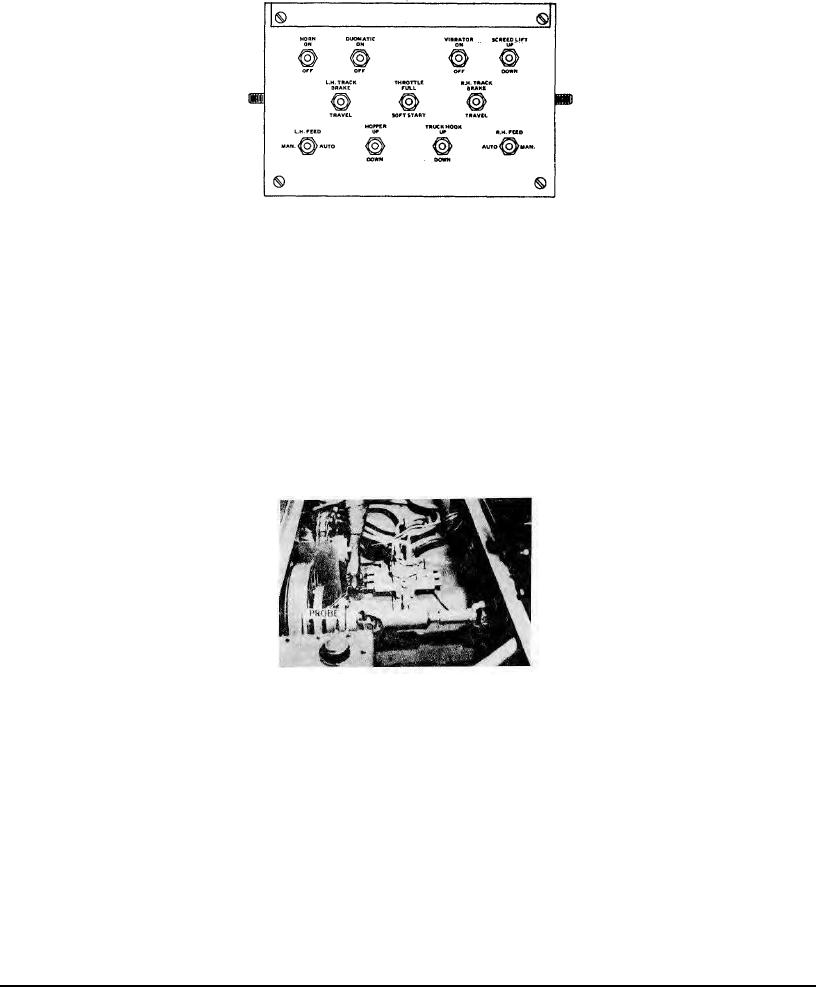

Figure 7 - Paver Control Console

The recommended way to make a fast accurate check of the hydraulic system electrical components and the valve

units they control is as follows:

A - With paver engine stopped, set Control Key Switch to ON.

B - Using a small probe such as an Allen wrench (See Figure 8) exert finger pressure on the manual operating pin

of the solenoid valve for the troublesome system. (Refer to Figure 2 for correct coil location). Have the correct switch

toggle moved back and forth through all positions and feel for the "throw" of the valve plunger and spool. If a definite

back and forth movement is felt it is unlikely that any electrical or solenoid trouble is causing the problem. If no

movement can be felt in that solenoid, but can be felt in other solenoids you test, proceed as follows:

The entire solenoid valve control system is 12 Volt D.C. and can be worked on safely. When a suspected system

has been checked out as described in paragraph above and found to be bad, make the following elementary checks of

the wiring in order to restore a troublesome system to normal operation.

With the paver engine stopped and the Control Key Switch ON,

1 - Disconnect the hot wire from the coil at the quick connector.

2 - With the console toggle switch set to operate the troublesome function of the system, make a quick, light,

brushing contact of the hot wire with the ground wire screw to which the ground wire of the coil is connected. There

should be a visible sparking if electrical current is flowing to the end of the wire.

Figure 8 - Method Of Probe Testing Solenoid Valves

CAUTION: If a firm steady grounding contact is made the control system

overload protector will function and will have to be re-set.

(a) If there is a spark, check the ground wire connection of the coil for a break or loose connection.

(b) If there is no spark, proceed with Step 3.

3 - If the hot wire does not spark when tested as described in Step 2 above, loosen the four screws in console switch

panel and carefully tilt the panel to make the switch terminals and wiring accessible. Using a short piece of single

conductor insulated wire with ends bared, jumper from the center terminal to each of the outer terminals of the switch

which operates the troublesome unit. As this is done a second person should be making the spark test with the loose hot

wire at the solenoid.

(a) If there is a spark at the solenoid hot wire when one combination of switch terminals is jumpered the toggle

switch is defective and should be replaced.

(b) If there still is no spark at the solenoid hot wire despite the switch terminal jumpering, proceed with Step 4.

4 - If no sparking occurs at the solenoid hot wire when the switch terminals are jumpered, carefully touch the short

jumper wire to the center terminal of the switch and make a quick, light, brushing contact of the wire with a bare area of

the console case.

(a) If sparking occurs at the console case the cause of unit failure is probably an "open" or break

Page 35