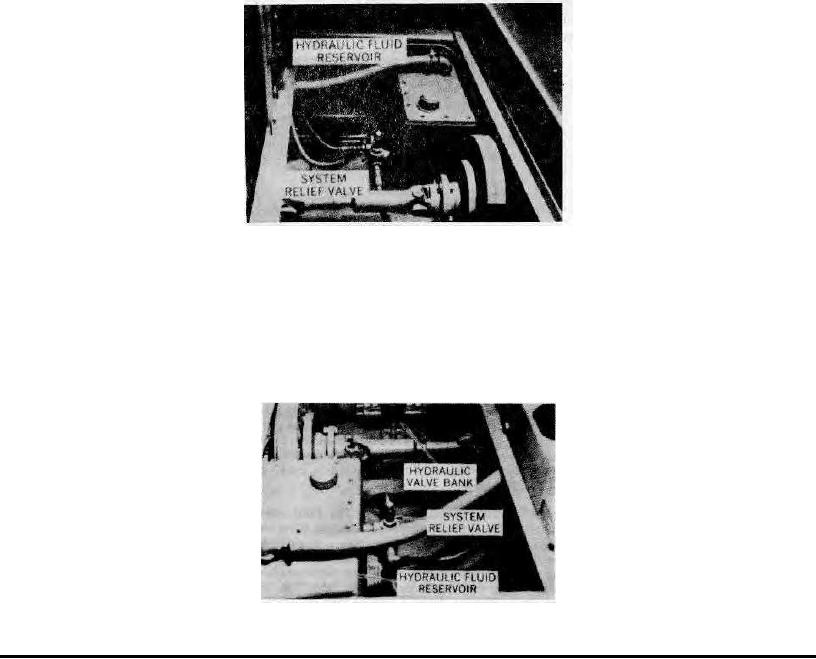

HYDRAULIC SYSTEM - General (Figures 1 & 2)

(1) The hydraulic pump which maintains the flow of hydraulic fluid through the paver system is a direct driven

unit. The engine must be at full throttle in order to develop the pump speed required for satisfactory fluid delivery. The

pump draws fluid from the reservoir and circulates it through the solenoid bank and filter unit back to the reservoir.

The solenoid operated hydraulic valves which make up the valve bank are controlled by toggle switches on the

operator's console. These spool type valves direct the flow to and from the various hydraulic cylinders which operate the

Screed Lift and Hopper Wings. When a spool is shifted to direct flow to a cylinder, pressure builds in that system

sufficient to move the cylinder piston and operate the assembly.

A pressure relief valve attached to the reservoir limits the build-up of system pressure to approximately 1500

P.S.I. any time the free return of fluid is restricted by diversion to a cylinder.

A holding valve in the screed lift system locks the screed hydraulically at any degree of elevation so that it cannot

creep downward due to its weight. Pump pressure is required to unlock this valve and the screed should be lowered with

the engine running fast enough to prevent a jerky descent of the screed due to intermittent "unlocking" of the holding

valve.

A throttle valve in the screed lift system limits the speed of screed descent to a safe rate.

A filter condition gauge on the filter unit in the fluid return line to the reservoir gives a visible indication of the

renewable element's condition. This gauge indicates the relative pressure required to force returning fluid through the 10

micron element. The gauge is only intended for this purpose and does not show paver system operating pressures. (For

recommended gauge readings see "Filter Gauge Readings" paragraph, Item 5) A by-pass feature is included in the filter

assembly so that a clogged element cannot stop the return flow of hydraulic fluid to the reservoir and interrupt system

operation. Important! The paver should not be operated with a clogged filter as an accelerated wearing of vital working

parts may occur and their service life will be shortened.

RH Sub-deck Area - (Walkway Removed)

Figure 3

The components which make up the hydraulic system will perform efficiently and have a long service life if the

following basic service requirements are consistently met.

(2) Fluid Level Check - (Figure 5) Maintain hydraulic fluid supply in reservoir at sight glass level. Fluid capacity

with all lines, components, and reservoir properly filled is approximately 10 gallons.

Use Texamatic Type F automatic transmission fluid only! Do not substitute other fluids. IMPORTANT - All fluid

being added to the reservoir must be completely free of foreign particles and contaminants. All maintenance work

performed on the system must be accomplished without introducing any solid particles which can find their way into

vital operating components.

RH Sub-deck Area - (Walkway Removed)

Figure 4

Page 33