Engine Tune-Up

torque of the adjusting screws is 24-36 in-lbs (3-4 Nm).

2. With the engine at operating temperature and no-

12. When all of the injector rack control levers are

load on the engine, place the speed control lever in the

adjusted, recheck their settings. With the control tube

maximum speed position. Turn the high-speed spring

lever in the full-fuel position, check each control rack as

retainer in (Fig. 6) until the engine is operating at the

in Step 7. All of the control racks must have the same

recommended no-load speed. Use an accurate hand

"spring" condition with the control tube lever in the full-

tachometer to determine the engine speed.

The

fuel position.

maximum no-load speed varies with the full-load

operating speed.

13. Insert the clevis pin in the fuel rod and the injector

control tube levers.

3. Hold the spring retainer and tighten the lock nut.

14. Turn the idle speed adjusting screw in until it

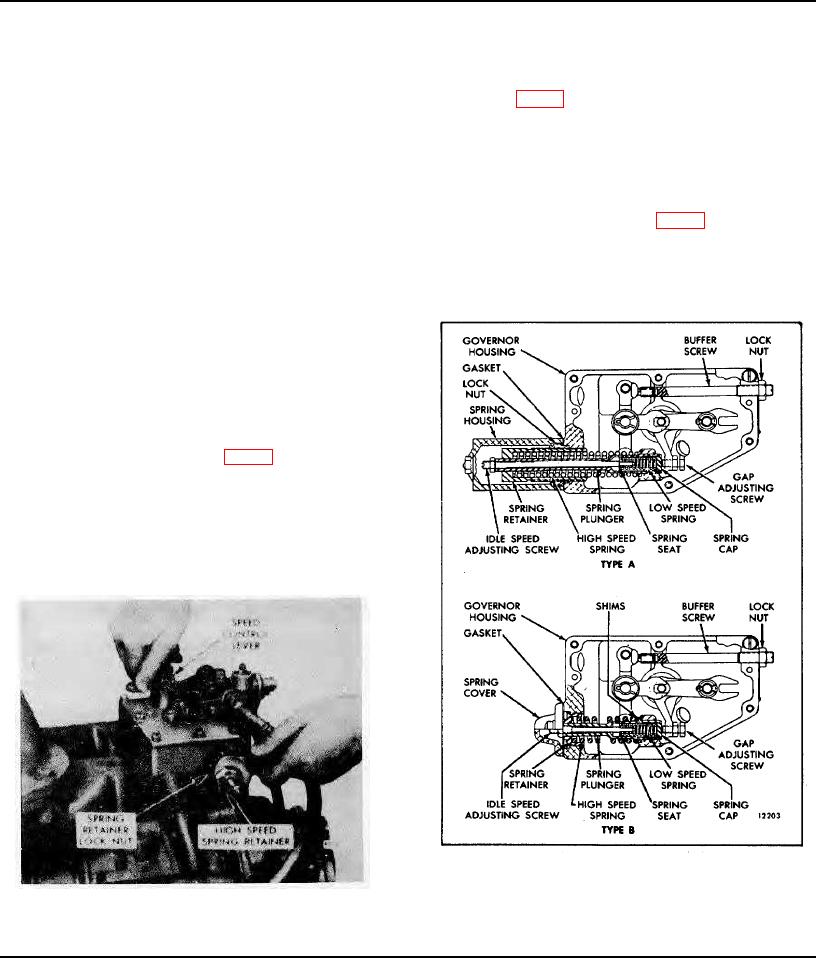

TYPE B GOVERNOR SPRINGS (Fig. 7):

projects 3/16" from the lock nut to permit starting the

1.

Start the engine and after it reaches normal

engine.

operating temperature, remove the load from the

15. Use new gaskets and replace the valve rocker

engine.

covers.

Adjust Maximum No-Load Engine Speed

All governors are properly adjusted before leaving the

factory.

However, if the governor has been

reconditioned or replaced, and to ensure the engine

speed will not exceed the recommended no-load speed

as given on the engine option plate, set the maximum

no-load speed as follows:

TYPE A GOVERNOR SPRINGS (Fig. 7):

1. Loosen the lock nut with a spanner wrench and back

off the high-speed spring retainer several turns. Then

start the engine and increase the speed slowly. If the

speed exceeds the required no-load speed before the

speed control lever reaches the end of its travel, back

off the spring retainer a few additional turns.

Fig. 7 - Governor Spring Assemblies

Fig. 6 - Adjusting Maximum No-Load Engine

Speed

Page 89