Fuel, Oil and Coolant Specifications

Always follow the supplier's recommendations on inhibitor usage and handling.

NOTE: Methoxy Propanol base permanent antifreeze (such as Dowtherm 209, or

equivalent) must be re-inhibited only with compatible corrosion inhibitor systems.

ANTIFREEZE

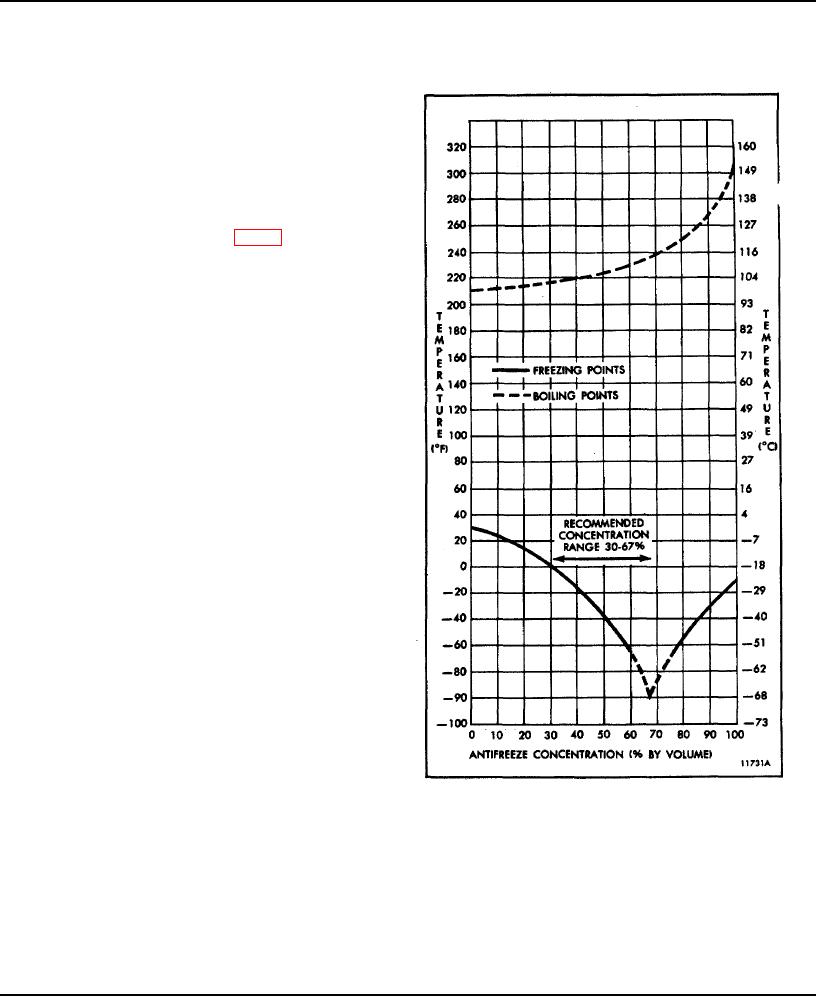

When freeze protection is required, a permanent antifreeze

must be used. An inhibitor system is included in this type

of antifreeze and no additional inhibitors are required on

initial fill if a minimum antifreeze concentration of 30% by

volume is used. Solutions of less than 30%, concentration

do

not

provide

sufficient

corrosion

protection.

Concentrations over 67% adversely affect freeze

protection and heat transfer rates (Fig. 4).

Methoxy Propanol base antifreeze is not recommended for

use in Detroit Diesel engines due to the presence of

fluoroelastomer (Viton '0') seals in the cooling system.

Before installing ethylene glycol base anti-freeze in an

engine previously operated with Methoxy Propanol, the

entire cooling system should be drained, flushed with clean

water and examined for rust, scale, contaminants, etc. If

deposits are present, the cooling

system must be chemically cleaned with a commercial

grade heavy-duty de-scaler.

Ethylene glycol base antifreeze is recommended for use in

Detroit Diesel engines. Methyl alcohol antifreeze is not

recommended because of its effect on the non-metallic

components of the cooling system and because of its low

boiling point.

The inhibitors in permanent antifreeze should be

replenished at approximately 500 hour or 20,000 mile

intervals with a non-chromate inhibitor system.

Commercially available inhibitor systems may be used to

re-inhibit antifreeze solutions.

Sealer Additives

Several brands of permanent antifreeze are available with

sealer additives. The specific type of sealer varies with the

manufacturer. Antifreeze with sealer additives is not

recommended for use in Detroit Diesel engines due to

possible plugging throughout various areas of the cooling

system.

GENERAL RECOMMENDATIONS

All Detroit Diesel engines incorporate pressurized cooling systems which normally operate at temperatures higher than

non-pressurized systems. It is essential that these systems be kept clean and leak-free, that filler caps and pressure

relief mechanisms be correctly installed at all times and that coolant levels be properly maintained.

WARNING: Use extreme care when removing a radiator pressure control cap from an

engine. The sudden release of pressure from a heated cooling system can result in a

loss of coolant and possible personal injury (scalding) from the hot liquid.

1. Always use a properly inhibited coolant.

Page 74