Engine Tune-Up

EXHAUST VALVE CLEARANCE ADJUSTMENT

The correct exhaust valve clearance at normal engine operating temperature is important for smooth,

efficient operation of the engine.

Insufficient valve clearance can result in loss of compression, misfiring cylinders, and eventually burned valve seats and

valve seat inserts. Excessive valve clearance will result in noisy operation,

especially in the low speed range.

Whenever the cylinder head is overhauled, the exhaust valves reconditioned or replaced, or the valve operating

mechanism is replaced or disturbed in any way, the valve clearance must first be adjusted to the cold setting to allow for

normal expansion of the engine parts during the engine warm-up period. This will ensure a valve setting which is close

enough to the specified clearance to prevent damage to the valves when the engine is started.

All of the exhaust valves may be adjusted, in firing order sequence, during one full revolution of the crankshaft. Refer to

the General Specifications at the front of the manual for the engine firing order.

TWO CYLINDER VALVE HEADS

Cold Engine

1. Place the speed control lever in the idle speed position.

If a stop lever is provided, secure it in the no-fuel

position.

2. Remove the loose dirt from the valve rocker cover(s)

and remove the cover(s).

3. Rotate the crankshaft, manually or with the starting

motor, until the injector follower is fully depressed on

the cylinder to be adjusted.

CAUTION: If a wrench is used on the

crankshaft bolt, do not turn the engine in

a left-hand direction of rotation as the

bolt will be loosened.

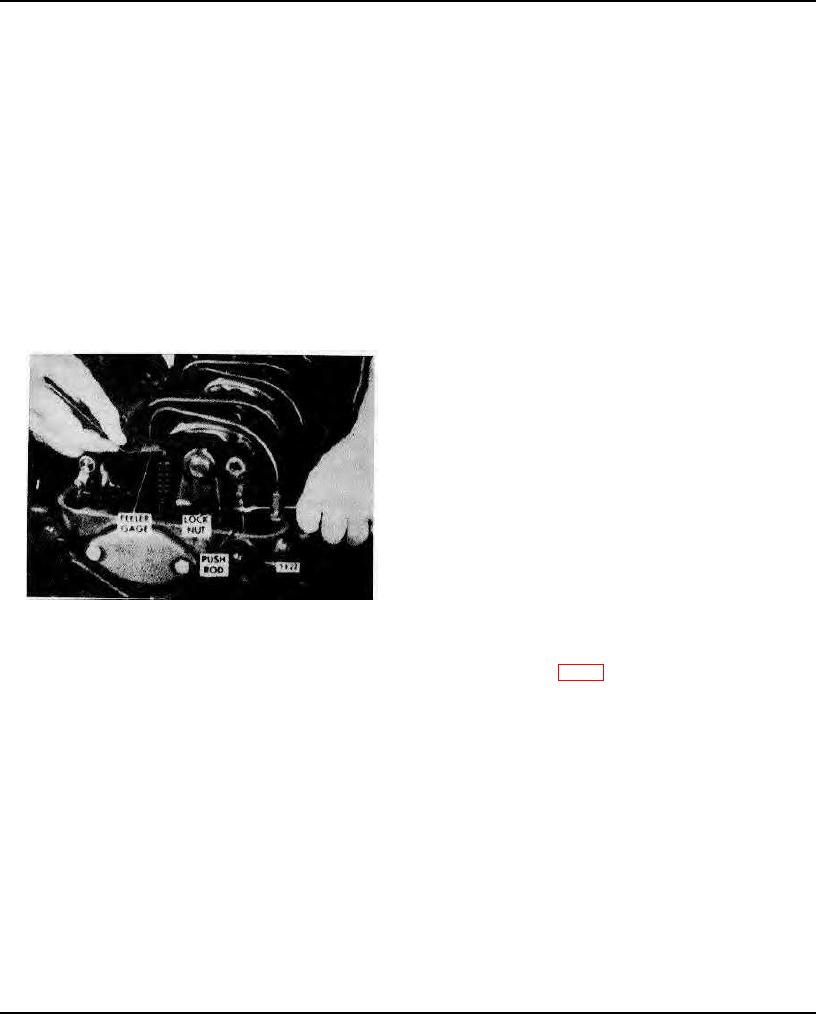

Fig 1. Adjusting Valve Clearance (Two-Valve

4. Loosen the exhaust valve rocker arm push rod lock

Cylinder Head)

nut.

5. Place a .012" feeler gage, J 9708, between the valve stem and the rocker arm (Fig. 1). Adjust the push rod to

obtain a smooth pull on the feeler gage.

6. Remove the feeler gage. Hold the push rod with a 5/16"wrench and tighten the lock nut with a 1/2 "wrench.

7. Recheck the clearance. At this time, if the adjustment is correct, the .010" gage will pass freely between the end of

the valve stem and the rocker arm and the .012" gage will not pass through.

8. Check and adjust the remaining valves in the same manner as outlined above.

Hot Engine

Maintaining normal engine operating temperature is particularly important when making the final valve clearance

adjustment. If the engine is allowed to cool off before setting any of the valves, the clearance, when running at full load,

may become insufficient.

1. With the engine at normal operating temperature (160-185F or 71-85C), recheck the exhaust valve clearance with

feeler gage J 9708. At this time, if the valve clearance is correct, the .008"gage will pass freely between the end of the

valve stem and the rocker arm and the .010"gage will not pass through. Readjust the push rod, if necessary.

2. After the exhaust valve clearance has been adjusted, check the fuel injector timing.

Page 78