TM 5-3895-385-23-1

0192

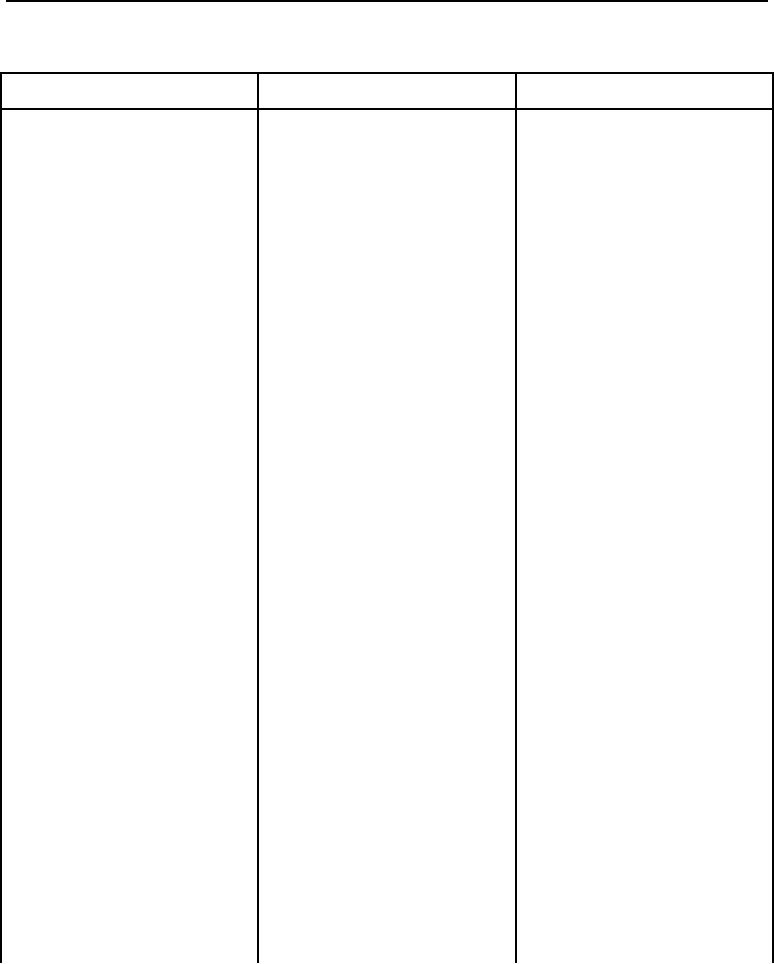

Table 1. Right Screed Horn Keypad Fault Troubleshooting Procedures -- Continued.

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

2. If no continuity is present,

proceed to next test.

2. Measure for continuity (WP

1. If continuity is present, replace

0443, Vol 3) between bulkhead

bulkhead hydraulic manifold

wiring harness W11 J2 Pin E

wiring harness (WP 0377, Vol 2).

and all other pins on the

bulkhead wiring harness W11 J2

(WP 0451, Vol 3, Figure 29).

2. If no continuity is present,

proceed to next test.

3. Measure for continuity (WP

1. If continuity is present, replace

0443, Vol 3) between bulkhead

bulkhead hydraulic manifold

wiring harness W11 J2 Pin F

wiring harness (WP 0377, Vol 2).

and all other pins on the

bulkhead wiring harness W11 J2

(WP 0451, Vol 3, Figure 29).

2. If no continuity is present,

proceed to next malfunction.

14. Screed wiring harness has an

1. Measure for continuity (WP

1. If continuity is present, proceed

open circuit.

0443, Vol 3) between screed

to next test.

wiring harness W6 J2 Pin D and

W6 J4 Pin A (WP 0451, Vol 3,

Figure 21 and 22).

2. If no continuity is present,

replace screed wiring harness

(WP 0384, Vol 2).

2. Measure for continuity (WP

1. If continuity is present, proceed

0443, Vol 3) between screed

to next test.

wiring harness W6 J2 Pin E and

W6 J4 Pin B (WP 0451, Vol 3,

Figure 21 and 22).

2. If no continuity is present,

replace screed wiring harness

(WP 0384, Vol 2).

3. Measure for continuity (WP

1. If continuity is present, proceed

0443, Vol 3) between screed

to next malfunction.

wiring harness W6 J2 Pin F and

W6 J4 Pin C (WP 0451, Vol 3,

Figure 21 and 22).

0192-11