TM 5-3895-385-23-1

0192

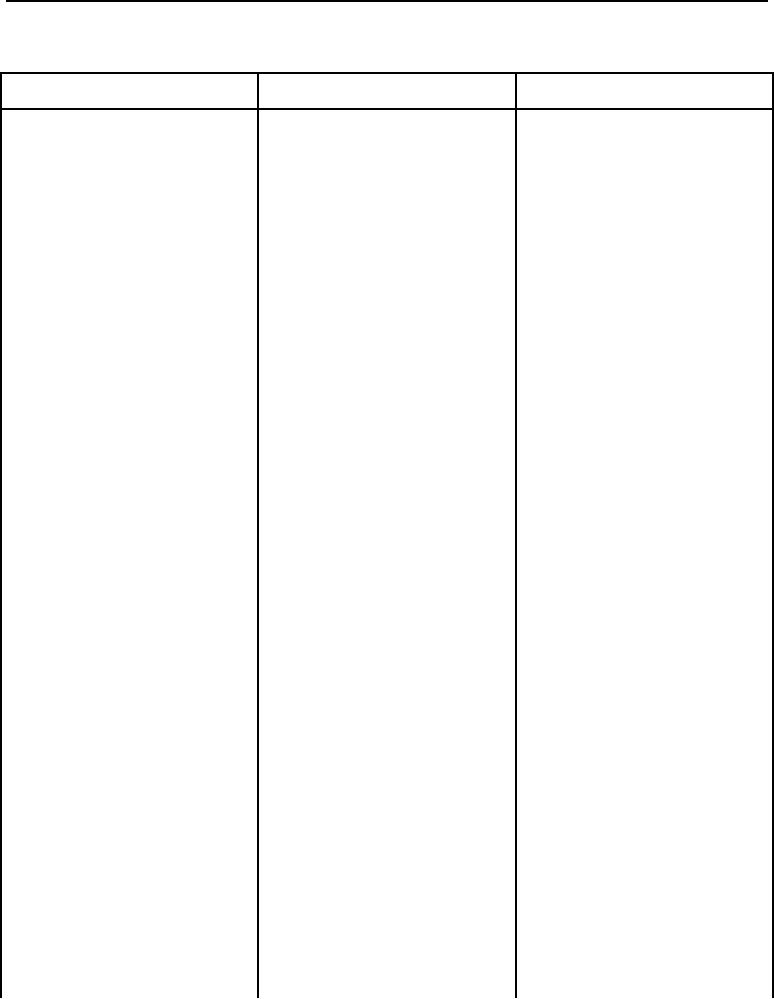

Table 1. Right Screed Horn Keypad Fault Troubleshooting Procedures -- Continued.

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

2. If communication cable is found

disconnected, reconnect

communication cable properly.

3. If no damage or loose

connection is found, proceed to

next malfunction.

5. Communication cable C9 has

1. Disconnect communication cable

an open circuit.

C9 J1 from Y6 P1 (WP 0451, Vol

3, Figure 51).

2. Disconnect communication cable

C9 J2 from Y7 P1 (WP 0451, Vol

3, Figure 51).

3. Measure for continuity (WP

1. If continuity is present, proceed

0443, Vol 3) from C9 J1 pin A to

to next test.

C9 J2 pin A (WP 0451, Vol 3,

Figure 51).

2. If no continuity is present,

replace damaged

communication cable (WP 0386,

Vol 2).

4. Measure for continuity (WP

1. If continuity is present, proceed

0443, Vol 3) from C9 J1 pin B to

to next test.

C9 J2 pin B (WP 0451, Vol 3,

Figure 51).

2. If no continuity is present,

replace damaged

communication cable (WP 0386,

Vol 2).

5. Measure for continuity (WP

1. If continuity is present, proceed

0443, Vol 3) from C9 J1 pin C to

to next malfunction.

C9 J2 pin C (WP 0451, Vol 3,

Figure 51).

2. If no continuity is present,

replace damaged

communication cable (WP 0386,

Vol 2).

6. Communication cable C9 has

1. Measure for continuity (WP

1. If no continuity is present,

short circuit.

0443, Vol 3) from C9 J1 pin A to

proceed to next test.

every other pin on C9 J1 (WP

0451, Vol 3, Figure 51).

0192-6