TM 5-3895-385-23-1

0132

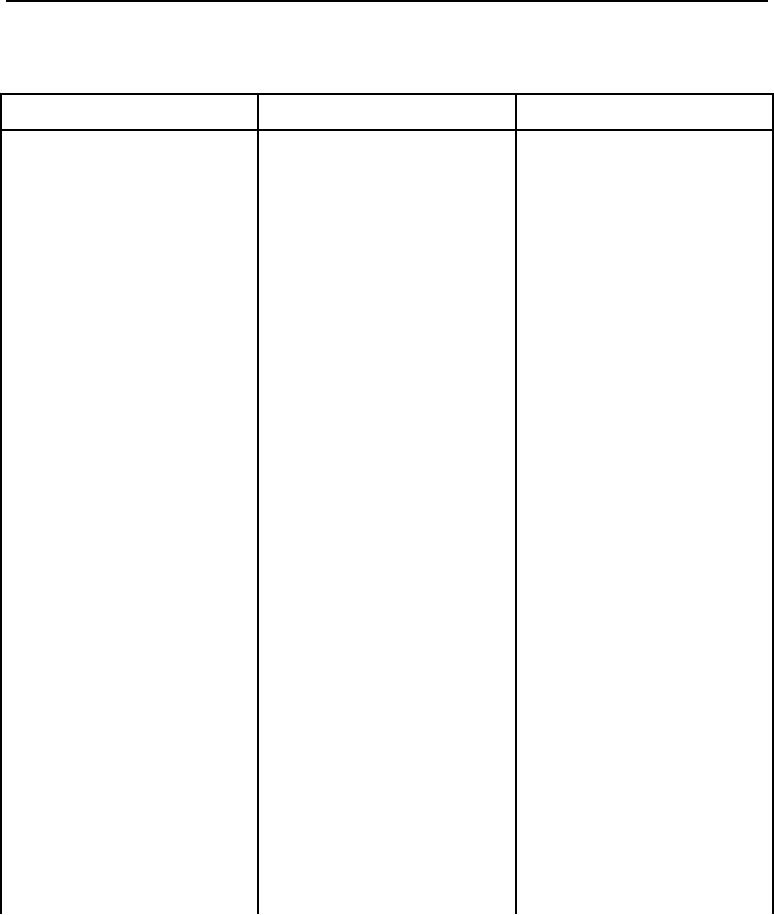

Table 1. Right Cutoff Close Fault Troubleshooting Procedures -- Continued.

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

3. Press right cutoff close key on

pedestal top (TM 5-3895-385-

10).

4. Measure voltage (WP 0443, Vol

1. If voltage reads a minimum of 22

3) between pin 1 and 2 on W10

Volts Direct Current (VDC),

J25 (WP 0451, Vol 3, Figure 28)

replace right cutoff hydraulic

while pressing right cutoff close

solenoid (WP 0312, Vol 2).

key on pedestal top.

2. If voltage reads below 22 VDC,

turn keyless engine switch to the

OFF position (TM 5-3895-385-

10), and proceed to next test.

5. Disconnect main wiring harness

W1 J8 from main manifold wiring

harness W10 J1 (WP 0451, Vol

3, Figure 27).

6. Turn keyless engine switch to

the AUX position (TM 5-3895-

385-10), but do not start engine.

7. Press right cutoff close key on

pedestal top (TM 5-3895-385-

10).

8. Measure voltage (WP 0443, Vol

1. If voltage reads a minimum of 22

3) from W1 J8 Pin 8 (WP 0451,

VDC, turn keyless engine switch

Vol 3, Figure 1) to a known good

to the OFF position (TM 5-3895-

ground while pressing right

385-10) and replace main

cutoff close key on pedestal top.

manifold wiring harness (WP

0376, Vol 2).

2. If voltage reads below 22 VDC,

turn keyless engine switch to the

OFF position (TM 5-3895-385-

10), and proceed to next

malfunction.

3. Output module (Electronic

1. Disconnect main wiring harness

Control Module (ECM)) has

W1 J3 from output module ECM

damage or loose pin.

(WP 0451, Vol 3, Figure 1).

0132-2