TM 5-3895-385-23-1

FIELD MAINTENANCE

BITUMINOUS MATERIAL PAVING MACHINE (BMPM)

MAIN HYDRAULIC MANIFOLD MALFUNCTION

INITIAL SETUP:

Test Equipment

References -- Continued

Hydraulic test kit (WP 0440, Vol 3, Item 59)

WP 0309, Vol 2

Personnel Required

WP 0442, Vol 3

91L

WP 0449, Vol 3

Assistant

Equipment Conditions

References

Engine off (TM 5-3895-385-10)

Hydraulic oil cool (TM 5-3895-385-10)

WP 0291, Vol 2

TROUBLESHOOTING PROCEDURES

NOTE

The maintainer should only be using this troubleshooting Work Package (WP) if directed to do so

from another troubleshooting WP. The procedures below assume it has been determined that

there is a loss of hydraulic pressure from the main hydraulic manifold to a hydraulic cylinder or

motor.

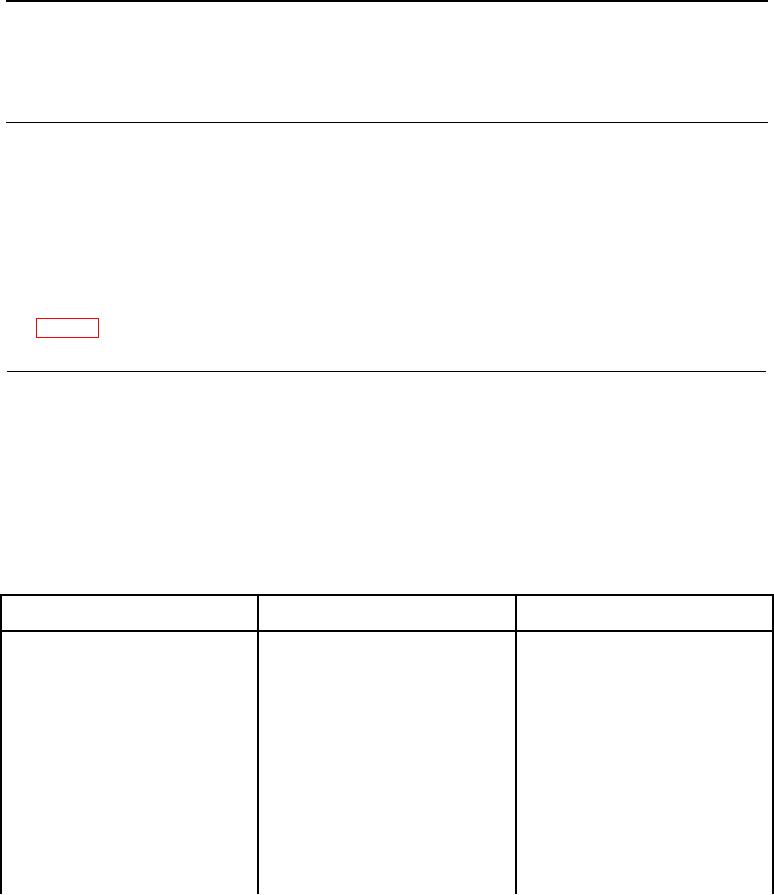

Table 1. Main Hydraulic Manifold Malfunction Troubleshooting Procedures.

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

1. Shut off valve closed.

Check shut off valves on hydraulic

1. If shut off valves are closed,

tank for open condition (WP 0449,

open hydraulic shut off valves.

Vol 3, Figure 6).

2. If shut off valves are open,

proceed to next malfunction.

2. Loss of hydraulic pressure.

1. Check hydraulic hoses from load

1. If leaks or damage is found,

sense hydraulic pump to main

replace damaged hydraulic hose

hydraulic manifold for leaks or

(WP 0291, Vol 2).

pinches (WP 0291, Vol 2).

2. If no leaks or damage is found,

proceed to next test.