TM 5-3895-373-34

2.62

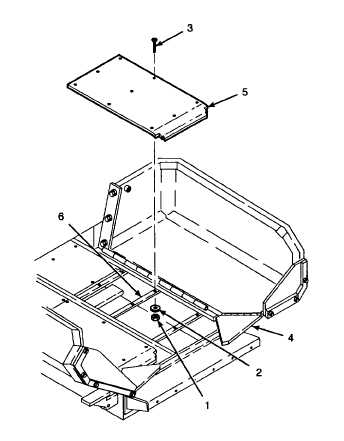

REPLACE CONVEYOR DRAG PLATES AND ENGINE INSULATION PAN - Continued.

C.

REPLACE - Continued.

4.

REPLACE FRONT CONVEYOR DRAG PLATE.

a.

Lift cover flap (4).

Front conveyor drag plate weighs 80 lbs (36

kg). To avoid personal injury, ensure two

persons are used for replacing drag plate.

Failure to do so may cause a serious injury.

NOTE

When front conveyor drag plate is installed,

ensure the leading curved edge of the drag

plate is toward the front of the paving

machine and facing downward.

b.

Slide front conveyor drag plate (5) over front

of the paving machine onto main frame

supports (6). Ensure the leading curved

edge of the drag plate is toward the front of

the paving machine and facing downward.

c.

Align cap screw holes on front conveyor

drag plate (5) with cap screw holes on main

frame supports (6).

Thread locking compound can cause eye

damage. Wear safety goggles/glasses when

using. Avoid contact with eyes. If

compound contacts eyes, flush eyes with

water and get immediate medical attention.

d.

Apply thread locking compound (Item 13,

Appendix B) to threads of socket head cap

screws (3).

e.

Insert socket head cap screws through front

conveyor drag plate (5) and into main frame

support (6).

f.

Install flat washers (2) and hex nuts (1) onto

socket head cap screws (3) from beneath

paving machine.

g.

Tighten hex nuts (1) to 37 lb-ft (50 N•m).

NOTE

FOLLOW-ON-TASKS:

Install conveyor chain assembly per paragraph 2.61.

Remove cribbing and jacks per TM 5-3895-373-20.

END OF TASK

2-860