TM 5-3895-373-34

C.

INSTALL - Continued.

Hydraulic fitting sealant can cause

eye damage or skin irritation. Wash

after skin contact. Wear safety

goggles/glasses when using. Avoid

contact with eyes or skin. If sealant

contacts eyes, flush eyes with water

and get immediate medical attention.

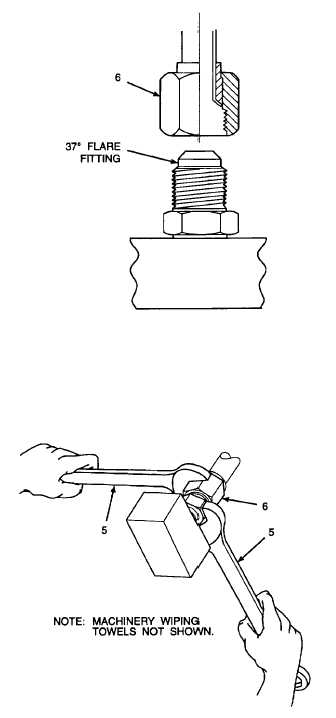

c.

Apply hydraulic fitting sealant to male threads

of 37° flare fittings. To protect against

hydraulic system clogging, do not apply

sealant to first thread turn of fittings.

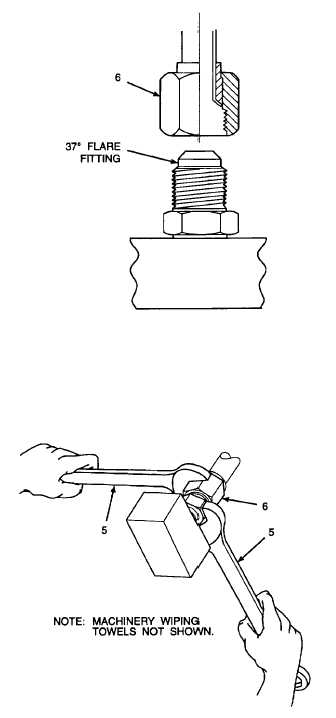

When tightening a tube or hose

coupling nut (6), secure mating fitting

with backup wrench (5). Failure to

secure

mating

fitting

can

stress

connecting components and may

result

in

failure

of

tube

and

accessories.

d.

Install and tighten coupling nut (6) on 37° flare

fitting. Using backup wrench, tighten coupling

nut until firmly seated. Check 37° flare fittings

for leakage during system startup. At that

time, leaking 37° flare fittings can be tightened

as needed to stop leakage.

NOTE

Large diameter hydraulic hoses take

a set during initial hours of operation.

When installing a replacement hose,

it

must

be

manually

shaped

to

duplicate curvature and orientation of

the hose it replaces.

e.

When replacing a 1-1/2 in. (38 mm) diameter

hose, install and finger tighten one end of hose

first. With help of another person, use pipe

wrenches to rotate and bend hose to

approximate curvature of used hose and

connect remaining loose end of hose to fitting.

GO TO NEXT PAGE

2-729