TM 5-3895-373-34

2.54.

REPAIR HYDRAULIC HOSES, TUBES, AND FITTINGS - Continued

C.

INSTALL - Continued.

3.

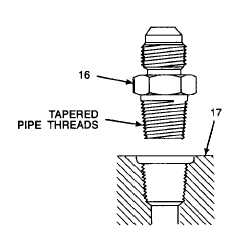

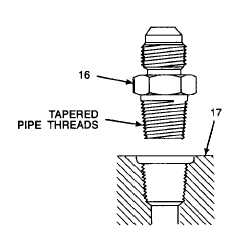

INSTALL TAPERED PIPE THREAD FITTINGS.

Pipe sealant can cause eye damage

or skin irritation. Wash after skin

contact. Wear safety goggles/glasses

when using. Avoid contact with eyes

or skin. If sealant contacts eyes,

flush

eyes

with

water

and

get

immediate medical attention.

a.

Apply pipe sealant to tapered pipe threads of

fitting (16).

b.

Install and tighten fitting (16) in mating

component (17) until snug. Connect tube or

hose per step c.

c.

Check fitting for leaks during system startup. If

leaking, loosen connecting tube or hose and

tighten hydraulic fitting, then retighten tube or

hose.

4.

INSTALL HYDRAULIC HOSES AND TUBES.

Use caution when installing tubes.

Do not bend kink, or twist tubes

during installation. Bends, kinks, and

twists can lead to tubing breaks

during equipment operation.

NOTE

If installing auxiliary or propulsion

system hoses and/or tubes, you

should

perform

pump

priming

procedure per step D at this time.

Some of the hydraulic hoses used in

the

paving

machine

are

routed

between and under other hoses and

components. This task refers to

these hoses as "embedded hoses

a.

If replacing an embedded hose, use a male-to-

male adapter from hydraulic systems test and

repair tool outfit (HSTRU) to connect used and

replacement hoses. Lubricate outer surface of

replacement hose and if possible, outer

surface of embedded hose, where it can be

reached, with petrolatum. With help from

another person, route replacement hose by

pulling free end of used hose from equipment.

NOTE

Refer

to

paragraph

2.55

for

installation

details

applicable

to

specific valve panel components.

b.

Route new hoses and tubes. Do not allow

tubes to bend, crimp, or twist. Provide

maximum bend radius at hose turns to prevent

hose crimping.

GO TO NEXT PAGE

2-728