TM 5-3895-373-34

2.54.

REPAIR HYDRAULIC HOSES, TUBES, AND FITTINGS - Continued

A.

REMOVE - Continued.

Hydraulic

oil

can

be

moderately

flammable and can be an irritant to

the

skin,

eyes,

and

respiratory

system. Avoid prolonged exposure.

Eye protection and rubber gloves

must be worn when working with

hydraulic oil.

Paving machine must be turned off

and hydraulic line pressure bled off

by slowly opening fitting prior to

opening the hydraulic circuit. A

pressurized hydraulic circuit can emit

a high- energy spray when a hose or

fitting is opened under pressure.

Failure to slowly bleed off hydraulic

pressure

may

result

in

serious

injuries to personnel.

When loosening a tube coupling nut,

secure - mating fitting with backup

wrench. Failure to secure mating

fitting

can

stress

connecting

components and may result in failure

of tubes and accessories.

d.

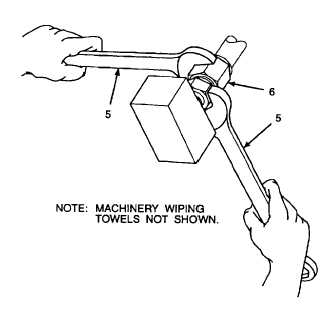

Install combination wrench or wrenches (5)

(Items

115

and

116,

Appendix

D)

on

connecting fittings. Wrap connection fittings

with machinery wiping towel (three layers,

minimum) to protect against contact with high

energy spray.

e.

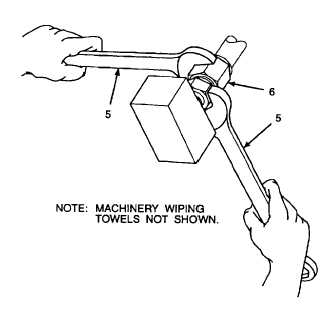

Slowly loosen tube coupling nut (6) about 1/8

turn. Allow several seconds for pressure to

bleed off, then unscrew tube coupling nut

another 1/8 turn. Continue this procedure until

pressure is bled off and tube coupling nut is

loose.

NOTE

If hydraulic hose is tightly embedded

in contamination. equipment, delay

hose

removal.

Embedded

hose

replacement is covered in INSTALL

procedures, step C.4.a.

f.

Tag and remove hoses, tubes, and fittings as

needed to replace faulty equipment or correct

hydraulic leaks. Plug and cap all open hose

fittings, tube fittings, and hydraulic circuit

fittings

to

protect

against

system

contamination.

g.

Remove preformed packings from o-ring boss

(ORB) type

fittings.

Discard

preformed

packings.

GO TO NEXT PAGE

2-724