TM 5-3895-373-34

2.39.

REPAIR TRACK TENSIONING CYLINDER - Continued

B.

CLEAN - Continued.

Compressed

air

used

for

cleaning

purposes will not exceed 30 psi (207

kPa). Use only with effective chip

guarding

and

personal

protective

equipment

(goggles/face

shield

and

gloves)

Failure

to

take

proper

precautions may result in severe injury

or loss of vision.

2.

USE 30 PSI (207 kPa) MAXIMUM COMPRESSED

AIR TO BLOW ANY FOREIGN MATERIAL FROM

SEAL GROOVES, INSIDE OF CYLINDER TUBE,

AND THREADED SURFACES. DRY PARTS

WITH A CLEAN, LINT-FREE CLOTH.

C.

INSPECT.

1.

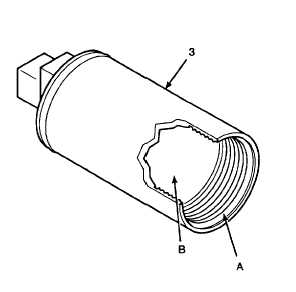

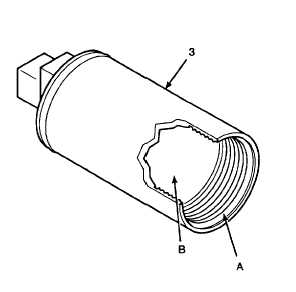

INSPECT CYLINDER TUBE.

a.

Run your finger along inside non-threaded

surface A of cylinder tube (3) and cylinder wall

B. Feel for any nicks, scratches, or sharp

edges that may damage preformed packings

and seals.

b.

Remove sharp edges of nicks or scratches

using crocus cloth.

c.

Replace cylinder tube (3) if scratches or pits

cannot be polished out, or if scratches exceed

0.5 in. (12, 7 mm) in length.

GO TO NEXT PAGE

2-538