TM 5-3895-373-34

2.20

REPAIR FUEL LIFT PUMP - Continued.

C.

INSPECT - Continued.

2.

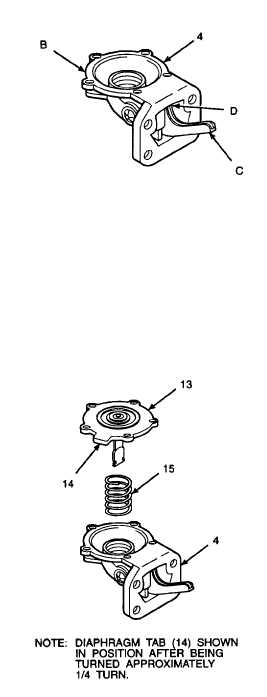

INSPECT BODY (4) FOR WARPED FLANGES,

WORN ROCKER ARM, AND WORN OR

BROKEN ROCKER ARM SPRING.

a.

Inspect body (4), surface B, for warped

flanges. Fit body and cover flanges

together with file marks aligned and check

for gaps between flanges.

b.

If body flange is warped, place emery cloth

on a flat surface and place body flange on

paper.

c.

Lightly sand flange until smooth. Check

body

and

cover

flange

fit.

Repeat

procedure as needed.

d.

Rinse body in warm, soapy water and use

compressed air to remove foreign matter.

Dry body with a clean, lint-free cloth.

e.

Inspect rocker arm surface C for wear and

rocker arm spring surface D for wear or

damage. Replace fuel lift pump if rocker

arm surface is worn or rocker arm spring is

worn or damaged.

3.

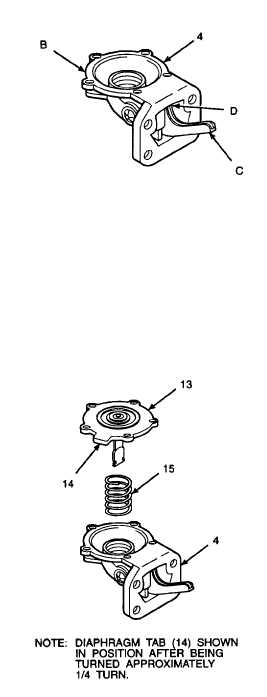

INSPECT DIAPHRAGM SPRING (15) FOR

WEAR, COMPRESSION, AND CORROSION.

4.

REPLACE

DIAPHRAGM

SPRING

(15)

IF

WEAR, COMPRESSION, OR CORROSION

ARE DETECTED.

D.

ASSEMBLE.

1.

INSTALL

DIAPHRAGM

SPRING

AND

DIAPHRAGM ON BODY.

a.

Install diaphragm spring (15) into body (4).

b.

Position diaphragm (13) on spring with tab

(14) on diaphragm positioned in line with

mounting flange on body.

c.

Press down hard on center of diaphragm.

Grasp

tab

on

diaphragm

and

turn

diaphragm

approximately

1/4

turn

clockwise

while

pressing

down

on

diaphragm.

Align

screw

holes

on

diaphragm with screw holes on body.

GO TO NEXT PAGE

2-294