TM 5-3895-373-34

B.

CLEAN.

1.

CLEAN ALL PARTS

IN

WARM,

SOAPY

WATER. ALLOW PARTS TO SOAK FOR

SEVERAL MINUTES.

2.

RINSE ALL PARTS IN WATER.

Compressed air used for cleaning will

not exceed 30 psi (207 kPa). Use only

with effective chip guarding and

personal

protective

equipment

(goggles/face

shield

and

gloves).

Failure to take proper precautions

may result in severe injury or loss of

vision.

3.

USE

30

PSI

(207

kPa)

MAXIMUM

COMPRESSED AIR TO BLOW WATER AND

FOREIGN MATTER FROM BODY, COVER,

AND FASTENERS.

4.

DRY ALL PARTS WITH A CLEAN, LINT-FREE

CLOTH.

C.

INSPECT.

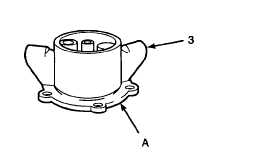

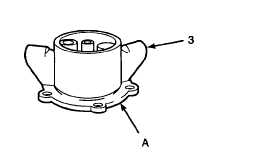

1.

INSPECT

COVER

(3)

FOR

WARPED

FLANGES AND STRIPPED THREADS.

a.

Inspect cover (3) surface A, for warped

flanges. Fit cover and body flanges

together with file marks aligned and check

for gaps between flanges.

b.

If cover surface is warped, place emery

cloth on a flat surface and place cover

flange on paper.

c.

Lightly sand flange until smooth. Check

cover

and

body

flange

fit.

Repeat

procedure as needed.

d.

Rinse cover in warm, soapy water and use

compressed air to remove foreign matter.

Dry cover with a clean, lint-free cloth.

GO TO NEXT PAGE

2-293