TM 5-3895-373-34

C.

TEST - Continued.

3.

BACK LEAKAGE TEST.

a.

With fuel injector mounted on test stand, apply a

pressure of 2204 psi (15 199 kPa) to fuel

injector.

b.

The amount of time for the pressure to fall to

1470 psi (10 133 kPa) should be between 15 to

35 seconds.

c.

If

fuel

injector

fails

back

leakage

test,

disassemble and clean per step B and retest. If

fuel injector fails a second time, discard fuel

injector.

4.

SEAT DRYNESS TEST.

a.

With fuel injector mounted on test stand, apply

pressure to fuel injector until nozzle assembly

opens. Hold a paper towel against nozzle

assembly tip, immediately after fuel spray stops,

for one minute.

b.

Ensure stain on paper towel is not larger than

1/2 in. in diameter after one minute with the

pressure maintained at 147 psi (1013 kPa)

below the setting pressure.

c.

If

fuel

injector

fails

seat

dryness

test

disassemble and clean per step B. If fuel

injector fails a second time, discard fuel injector.

D.

INSTALL.

1.

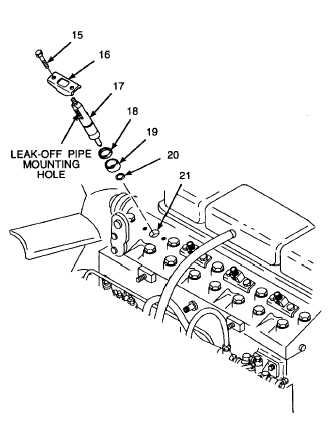

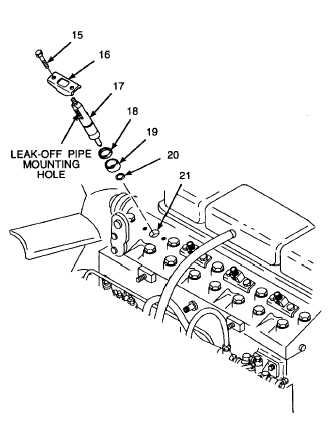

INSTALL FUEL INJECTOR.

a.

Install spacer (19) and gasket (18) onto fuel

injector (17).

NOTE

Ensure leak-off pipe mounting hole is

facing

away

from

cylinder

head

assembly during installation

of

fuel

injector.

b.

Install washer (20) onto end of fuel injector (17)

and install fuel injector into injector port (21).

c.

Install clamp (16) and bolts (15). Evenly tighten

bolts to 168 lb-in (19 N•m).

GO TO NEXT PAGE

2-245