TM 5-3895-373-34

C.

INSPECT.

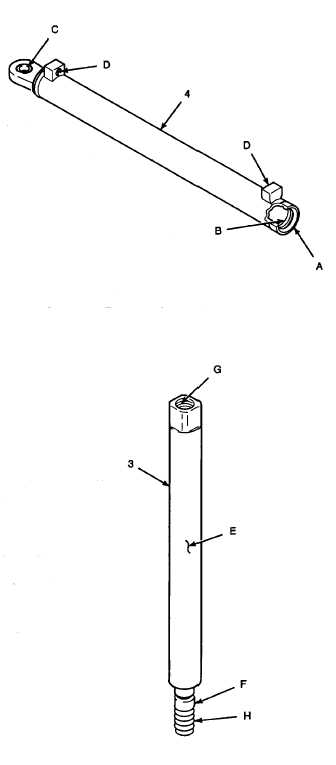

1.

INSPECT CYLINDER TUBE.

a.

Run your finger along the inside surface A

of cylinder tube (9) and retaining ring

groove surface B. Feel for any nicks,

scratches,

or

sharp

edges

that

may

damage preformed packings and seals.

b.

Remove sharp edges of nicks or scratches

using crocus cloth.

c.

Replace cylinder tube (4) if scratches or pits

cannot be polished out, and if scratch

exceeds 0.5 in. (12,7 mm) in length.

d.

Visually inspect cylinder tube (4) interior for

scoring or glazing using a strong light. If

scoring or glazing is detected, replace

cylinder tube.

e.

Check spherical bearing C for damage or

looseness. Replace spherical bearing if

damaged or loose. Refer to step D.1.

f.

Inspect cylinder tube (4) port threads D for

stripped or damaged threads.

g.

Replace cylinder tube (4) if stripped or

damaged threads are detected.

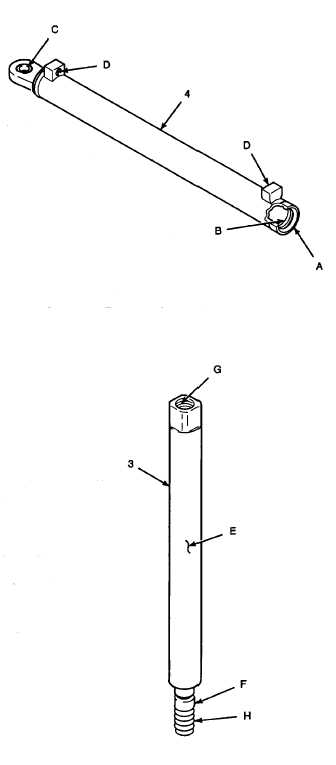

2.

INSPECT PISTON ROD.

a.

Run your finger along piston rod (3) surface

E. Feel for any scratches or sharp edges

that may damage preformed packings and

seals. Inspect circumference of piston rod

for scratches, pits, or wear that expose

base metal through chrome plating.

b.

Remove sharp edges of nicks or scratches

using crocus cloth.

c.

Replace piston rod (3) if scratches or pits

cannot be polished out, if scratch exceeds

0.5 in. (12,7 mm) in length, and base metal

is exposed through chrome plating.

d.

Run your finger along edge of packing

groove surface F and feel for nicks and

sharp edges. Remove sharp edges using

crocus cloth. If packing groove surface is

cracked or chipped, replace piston rod (3).

e.

Inspect piston rod (3) threaded surfaces G

and H for stripped or damaged threads.

f.

Replace piston rod (3) if stripped or

damaged threads are detected.

GO TO NEXT PAGE

2-1039