TM 5-3895-373-34

D.

REPAIR - Continued.

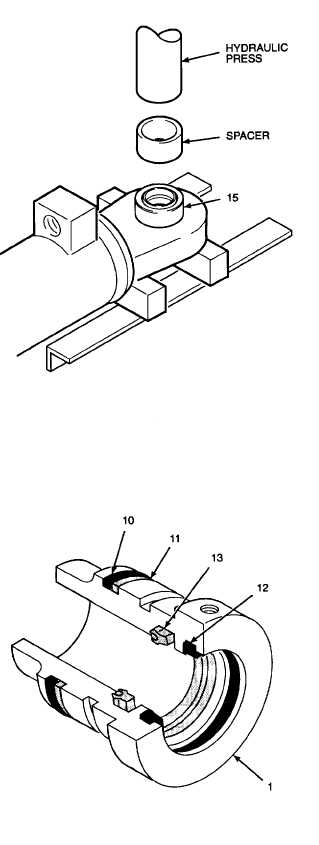

NOTE

Spherical bearing will require 500 to

700 lb-ft (2224 to 3114 N•m) to press

into cylinder tube base bearing bore.

c.

Place a spacer from universal puller kit onto

outer race of spherical bearing (15). Press

spherical bearing into base bearing bore.

E.

ASSEMBLE.

1.

INSTALL COMPRESSION CUP, RING WIPER,

PACKING RETAINER, AND O-RING INTO

CYLINDER HEAD.

Hydraulic oil can be moderately

flammable and can be an irritant to

the

skin,

eyes,

and

respiratory

system. Avoid prolonged exposure.

Eye protection and rubber gloves

must be worn when working with

hydraulic oil.

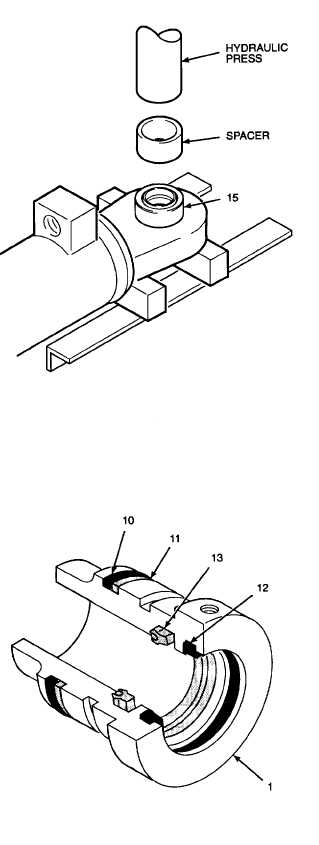

a.

Lubricate compression cup, ring wiper,

packing retainer, and o-ring with clean

hydraulic oil.

New seals and o-ring are distorted

during installation. Use care during

installation to prevent damage to

seals, o-rings, and seal grooves.

Bypass leakage can result from poor

installation.

b.

Twist compression cup (13) into a C-shape.

Install compression cup inside cylinder

head (1) and allow to snap into seal groove.

c.

Twist ring wiper (12) into a C-shape. Install

ring wiper inside cylinder head (1) and allow

to snap into seal groove.

d.

Install packing retainer (11) and o-ring (10)

on cylinder head (1).

GO TO NEXT PAGE

2-1043