TM 5-3895-373-20

14.6.

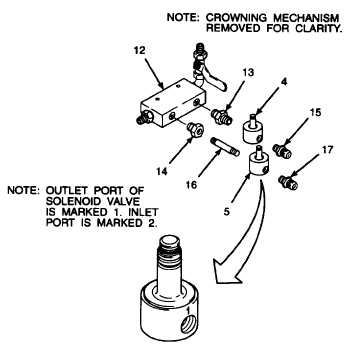

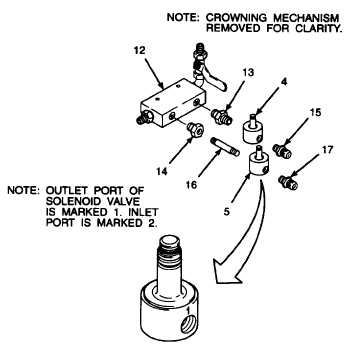

REPLACE/REPAIR BURNER FUEL SOLENOID VALVE - Continued.

C.

INSTALL.

1.

INSTALL FUEL SOLENOID VALVES.

Pipe sealant can cause eye damage

or skin irritation. Wash after skin

contact. Wear safety goggles/glasses

when using. Avoid contact with eyes

or skin. If sealant contacts eyes, flush

eyes with water and get immediate

medical attention.

Do not apply pipe sealant to first

three threads of adapters, pipe nipple

and pipe bushing. Apply only a light

coating of pipe sealant to threads.

Excessive amounts of pipe sealant

can cause clogging of fuel system

components.

a.

Apply pipe sealant to 1/8 in. pipe threads of pipe

nipple (13) and straight adapters (15 and 17),

both ends of pipe nipple (16), and male threaded

end of pipe bushing (14).

b.

Place solenoid valve (4) in a bench vise and

install pipe nipple (13) to inlet and straight

adapter (15) to outlet.

c.

Place solenoid valve (5) in a bench vise and

install straight adapter (17) to outlet, pipe nipple

(16) to inlet, and pipe bushing (14).

d.

Place manifold (12) into a bench vise and install

assembled solenoid valves (4 and 5). Install with

inlet port marked 2 toward manifold. Make sure

that stems on solenoid valves are pointing

straight up when fully tightened.

Thread locking compound solvent can cause eye

damage. Wear safety goggles/glasses when using.

Avoid contact with eyes. If solvent contacts eyes, flush

eyes with water and get immediate medical attention.

e.

Use thread locking compound solvent to clean

all residue from threads of bolts. Wipe off bolt

threads with a lint-free cloth.

GO TO NEXT PAGE

14-54