TM 5-3895-371-24 & P

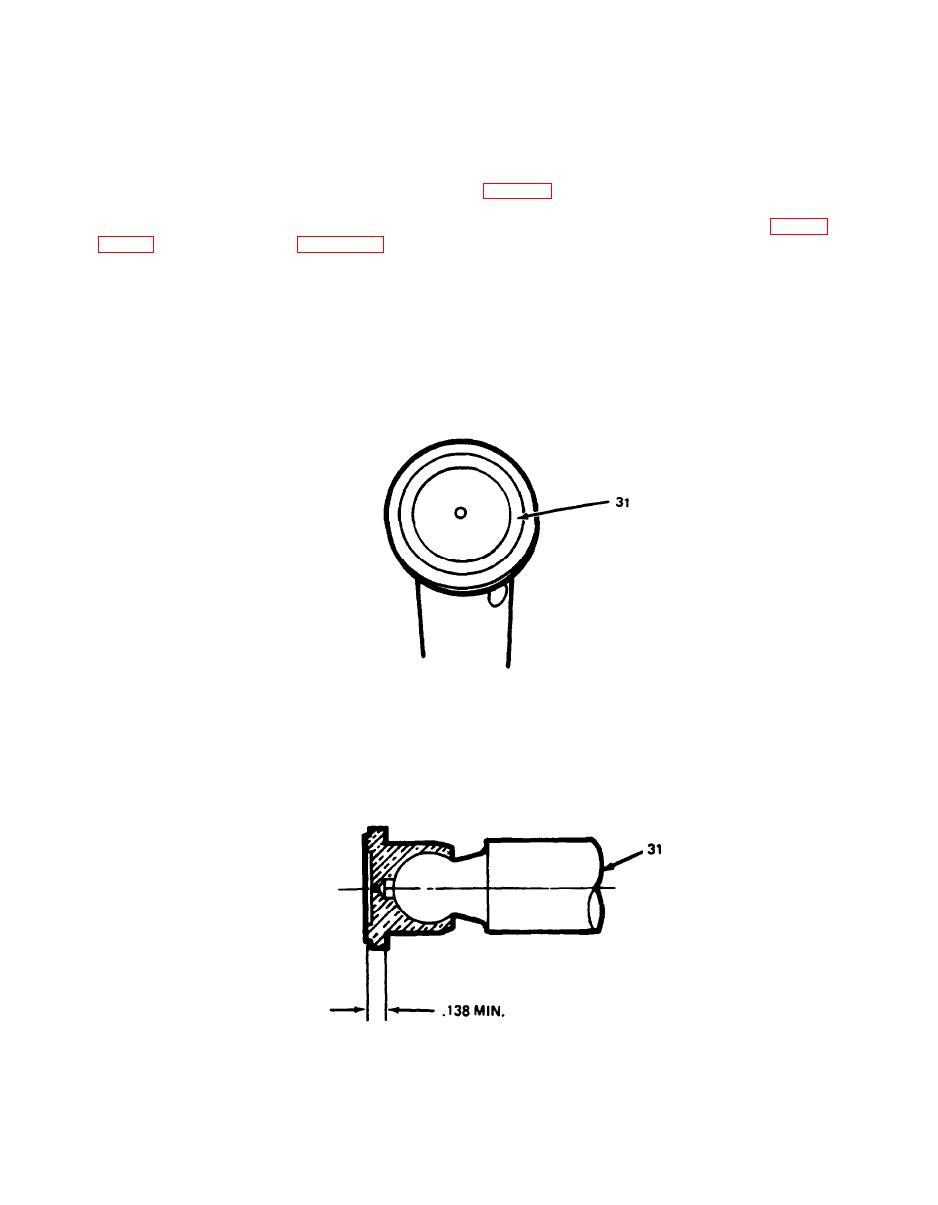

(10) With a push-pull motion, check for free play between bronze shoe, part of piston as-

sembly (31) and steel piston body. If any play can be felt, the piston must be discarded. Inspect bronze

piston shoes (31). During normal service, a dulling of the running surface is to be expected. If large

scratches that can be felt with a fingernail are present (fig. 3-32) make several short passes over 500 grit

emery paper on a lap surface. On the last few passes, place five to six sheets of emery paper as a cushion

under the top sheet to obtain the proper edge sharpness. Check the reworked piston assembly (31, fig.

34) with tolerance limits in figure 3-33. If piston shoe does not fall within tolerance limits, discard

reworked piston and replace. Check as follows:

(a) Check piston shoe for iron or steel particles imbedded in the running surface. If

present, discard the piston.

(b) Often, large scratches on the piston shoe running surface will "heal over" if placed

back in service. It is recommended, however, that all piston shoes with badly scratched running surfaces

be either reworked within tolerance limits or replaced.

Figure 3-32. Inspecting Piston Shoe.

Figure 3-33. Piston Shoe Rework Tolerance.

3-30