TM 53895-371-24 & P

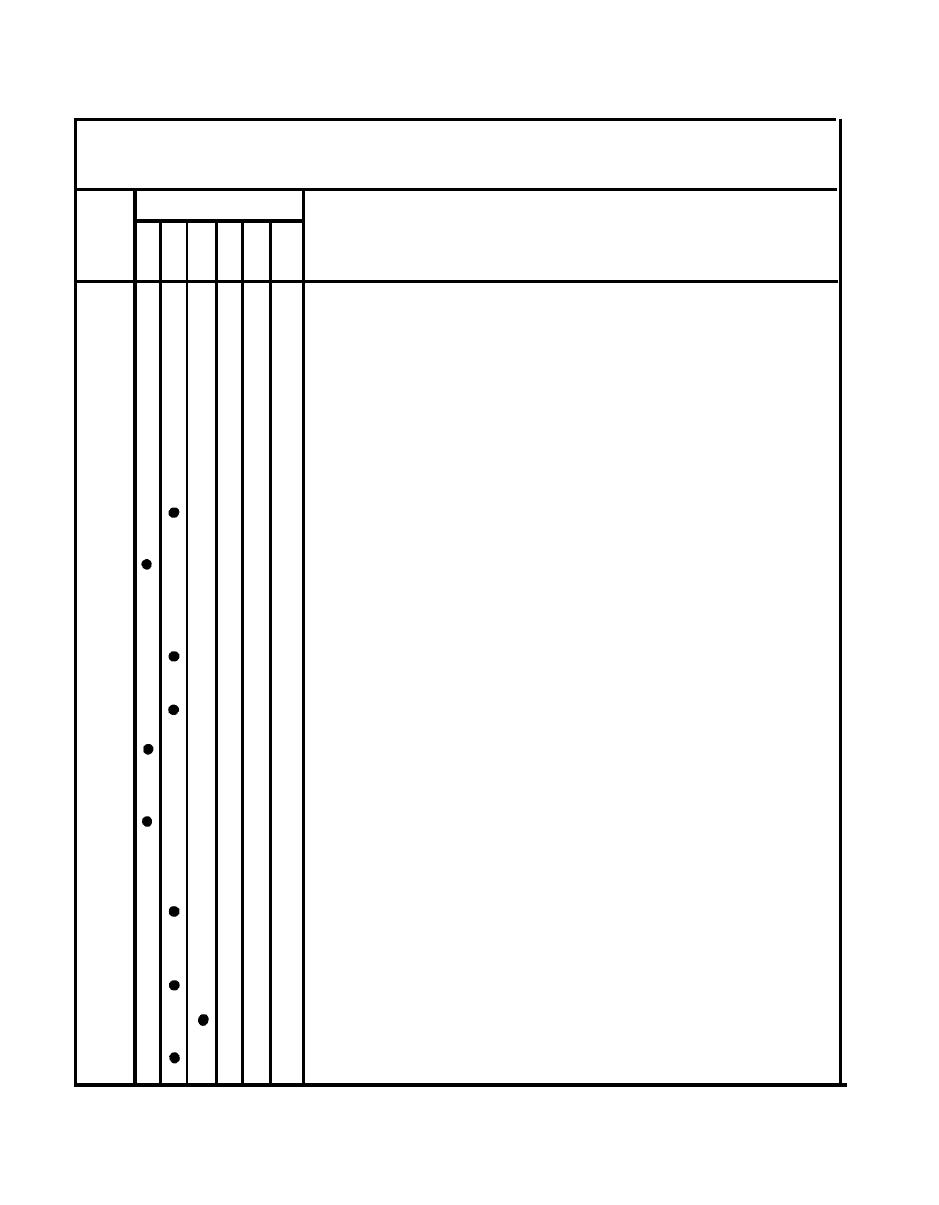

Table 2-1. ORGANIZATIONAL PREVENTIVE MAINTENANCE CHECKS AND SERVICES

A-Annually

B-Biennially

S-Semiannually

H-Hours

Q--Quarterly

M-Miles

ITEM

INTERVAL

ITEM TO BE INSPECTED

NO.

Q S

A

B

H

Ml

PROCEDURE :Check for and have repaired,filled,or adjusted

as needed.

NOTE

PERFORM OPERATOR/CREW PMCS PRIOR TO OR IN CON-

JUNCTION WITH ORGANIZATIONAL PMCS IF:

a. There is a delay between the daily operation of the equipment

and the organizational PMCS.

b.

Regular operator is not assisting/participating.

ELECTRICAL SYSTEM

Check wiring harness for corrosion and bare wires. Replace defective

1

wiring.

Check all lights for proper operation. Replace defective lamps and

2

lights.

DISTRIBUTOR BODY

Check material storage tank, subframe, tie downs and fasteners for

3

obvious damage, weld breaks. Notify DS Maintenance for repair.

4

Check that manhole cover seals properly. Repair as needed.

Check overflow pipe. Clean any material buildup in pipe.

5

UNIVERSAL DRIVE

Check universal drive and U-joints. Check for wear and cracks. Re-

6

place damaged U-joints.

HYDRAULIC SYSTEM

7

Check all hydraulic lines and fittings. If damaged, replace.

BURNER FUELSYSTEM

Check fuel lines and fittings. If damaged, replace.

8

Check burner fuel tank holding straps. If damaged, repair or replace.

9

Check burner assembly air hose for leeks. Replace if damaged.

10

24