TM 5-3895-371-10

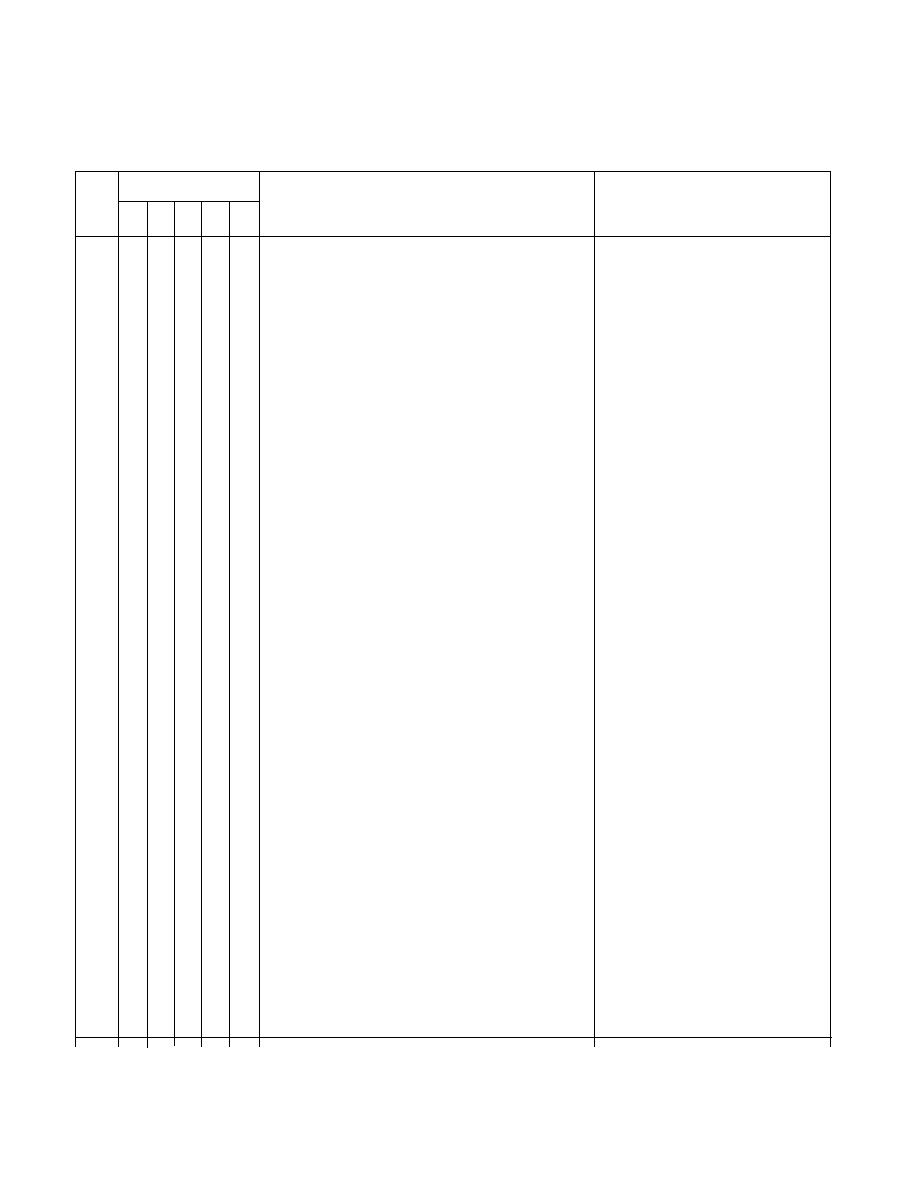

Table 3-1. Operator/Crew Preventive Maintenance Checks and Services - Continued

B - Before

D - During

A - After

W - Weekly

M - Monthly

Interval

ITEM TO BE INSPECTED

FOR READINESS REPORTING

Item

Procedure:

Check For And Have Repaired,

Equipment Is Not Ready/

No.

B

D

AWM

Filled Or Adjusted As Needed

Available If:

20

Check fuel tank for leaks

Class III leaks are evident

21

Check blower burner fuel line

strainer. If clogged, clean it.

22

Check blower air cleaner. If

oil is dirty, change oil.

23

Check burner valve strainer.

If clogged, clean it.

24

Check heater burners and flues

for insecure mounting.

Portable Burner

25

Check burner coil and vapor-

izing jet. If dirty, clean it.

26

Check portable burner gage.

Indicator is inoperative

Best operation at 45 psi.

Bitumeter Wheel Assembly

27

Check bitumeter wheel for

secure mounting and proper

operation.

28

Check bitumeter wheel air-

Indicator is inoperative

gage (at wheel) activated

or gage does not show

In cab and 120 psi is mini-

pressure.

mum pressure.

29

Check recording bitumeter.

Records in ft per minute

and feet traveled.

30

Check air lines for leaks.

Spray Bar

31

Check nozzle slots for cor-

rect angle (30 degrees) and

correct height above road

(12 inches above road).

3-7