TM 5-3895-371-10

(5)

Strainers - One is provided in the filling line (fig. 3-8), one in the discharge header (fig. 24) between the

pump and control valves, one in the manhole (fig. 3-5), one in the fuel lines (fig. 3-4), and one at each burner control valve

(6)

Transfer Valve - "Leakless" type Quick-action union connections for transferring material at full pump

capacity. Complete with Morrison Couplings for attaching filling hose or hand spray hose.

(7)

Pump - Heavy-duty, rotary gear type Capable of supplying bitumen to the 24-foot spray bar with sufficient

pressure to produce an even, fanlike spray from all nozzles at any rate of application within the distribution range of 1/10 to

1 gallon per square yard. Capacity, 400 gpm

(8)

Filling Line - Quick-acting, screw-clamp, hinged-type connection with Morrison Couplings, for connecting

filling hose Located in front of left operator's platform

e

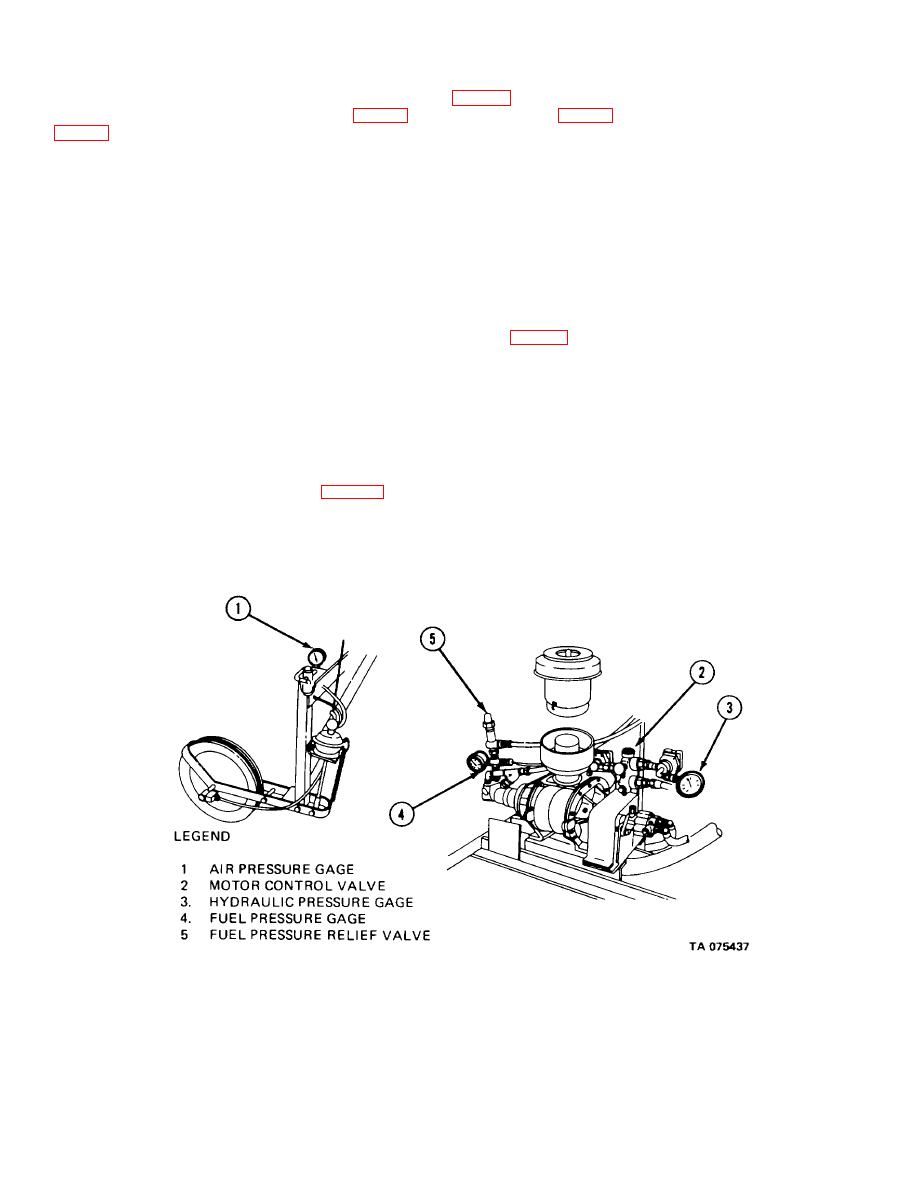

Pressure Gages and Control Valves. The gages and valve (fig. 2-5) provide the operator visual indications and

control of hydraulic oil pressure

(1)

Air Pressure Gage - Provides visual indication of the air pressure in the distributor system Indicates 0-160

psi Normal reading is 120 psi.

(2)

Motor Control Valve - The valve has an On/Off position to control the flow of hydraulic fluid to operate the

burner blower

(3)

Hydraulic Pressure Gage - (Fig. 2-5) provides visual indication of the hydraulic pressure developed in the

distributor system. Indicates 0-5000 psi. Maximum pressure is 4000 psi

(4)

Fuel Pressure Gage - Indicates the amount of fuel pressure applied to the burners to mix air for ignition.

Indicates 0-100 psi. Normal reading is between 10-15 psi.

Figure 2-5. Pressure Gages and Control Value.

2-8