APPENDIX O

Cleaning and Lubricating Paver

CLEANING PAVER

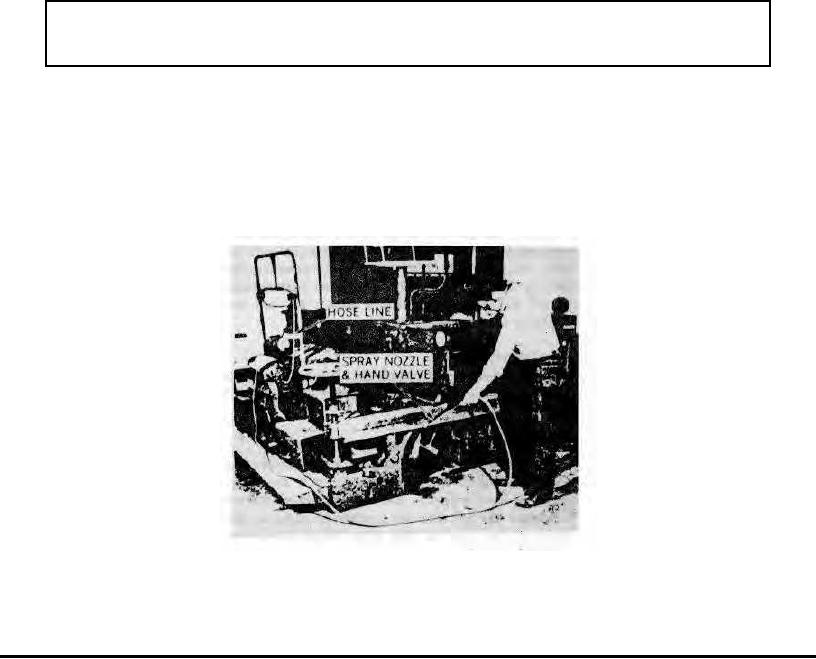

It is extremely important that the paver be thoroughly cleaned at the end of each day's operation! A spray

nozzle with 15 foot hose is attached to the pressure side of the screed heater fuel system. This permits the operator to

reach all areas of the paver which require cleaning and lubricating.

Method:

(1) Run engine at IDLE speed.

(2) Set valve selector switch to SPRAY-DOWN

(3) Push panel circuit breaker to ON

(4) Turn junction box burner switch to ON

(5) Depress hose line valve lever

Clean all parts of the paver which come in contact with asphalt. The track and track rollers, hopper, slat conveyors,

spreader screws, screed, drive chains, etc. all require cleaning at the end of each day. This holds true even if the paver

was actually used only a short time. Many paver troubles can be traced to improper cleaning! Fuel oil on the slat

conveyors and tracks provides the needed lubrication which prevents rapid wear. The spray should reach all track link

pins so that there is no squeaking as the paver moves. The slat conveyors should be operated during the spraying to be

sure that all of the slats and chain are reached.

IMPORTANT! Keep oil spray away from all electrical boxes, motors, generators, starters, etc. Do not

spray paver when it is parked on an asphalt mat! Move it to the side of the road where drainage of oil

and dissolved asphalt will not damage anything.

In addition to spray cleaning of the paver the following clean up practices should be routine.

1. Check for accumulation of asphalt in the heat vent holes along the top of the moldboard. This check can best be

made by feeling the exhaust of hot air when the heater is being operated (the upper vents become plugged when asphalt

spills over the moldboard when a material level too high above the screw is allowed to build up. Use a stiff wire to clean

out accumulated asphalt.

2. Periodically remove the screed plate as described in Screed Section 7 and clean the interior of all asphalt, sand,

and fine material. Failure to keep the inside of the screed plate clean will cause uneven distribution of heat to the screed

bottom and possible tearing of the mat surface.

Cleaning Paver with Screed Heater Fuel Spray Accessory

Figure 1

TRUCK ROLLERS

Two rollers located on the front of the hopper are lubricated before assembly and require no further lubrication.

However, these rollers should be cleaned often during operation to eliminate material build-up.

0-1