(g) Clean out the heater fuel tank.

(h) Clean out the heater; check the igniter tip

and porcelain. Be sure blower fan is tight. Set tips as

outlined in manual. Check and clean out pump. Be sure

the transformer is working.

WARNING: Cover must be over transformer at

all times.

2. Check over all wiring on the tractor, looking for

loose or bare wire. Tighten all connections on:

(a) Relays

(b) Toggle switches

(c) Limit switch on the reverse shifter bar

(d) Depth control limit switches

(e) Manual override switch

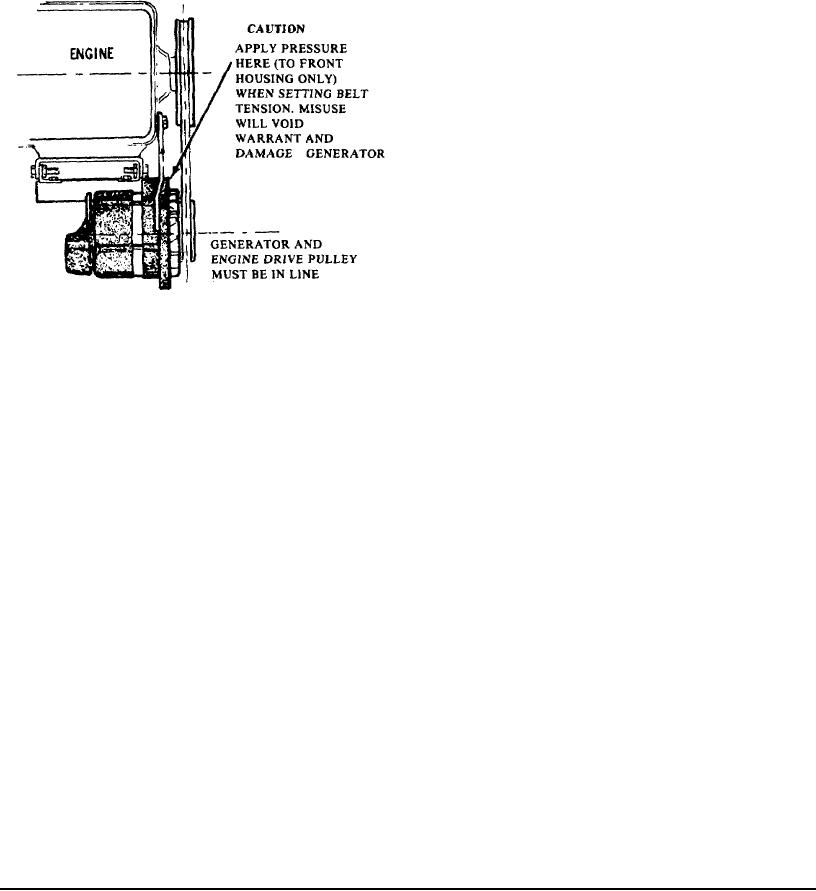

(f) Check the 125 volt generator V-belt drive

and mounting. Check pulley set screws for tightness.

(g) Check the 12 VDC Generator V-belt drive

Correct Alignment of Generator Pulley

and mounting. Check pulley set screws for tightness.

Figure 60

3.

Refer to the engine manufacturer's manual

for all periodic maintenance instructions. Strict compliance

SEASONAL OVERHAUL

with these instructions will help assure steady and efficient

Iowa Manufacturing Company strongly recommends

operation of the vital power plant.

that each paver be given a seasonal overhaul if it has

4. Drain and flush the transmission and transfer

accumulated at least 500 operating hours during that

cases and fill with the correct quantity and type of oil.

season. By so doing the paver owner prepares for the next

5. Check electric clutches - make sure each

season by eliminating many of the potential break-down

clutch is getting the proper amount of current. This should

possibilities in advance.

be a minimum of 11.4 volts when machine is in operation.

The following procedures are recommended for

Make sure all clutch settings are maintained as noted in

conditioning the CEDARAPIDS Paver for the coming

Electric Clutch Paragraphs, this Section.

season.

6. Remove the slat and screw conveyors.

1. Separate the screed from the tractor unit by

(a) The liners for the slat conveyor may need

unbolting the arm at the pivot points, loosen the screed

replacing.

lifting cables and unplug the electric cable at the quick-

(b) If the chain of the slat conveyor is starting

disconnect.

to show wear it may be reversed.

(a) Remove the moldboard from the screed.

(c) Check the conveyor sprockets if they show

(b) Check all holes that allow heat to enter the

excess wear, replace at this time.

moldboard chambers to see that they are open.

(d) Check all the roller bearings and tighten all

(c) Check all Eriez Vibrators for the proper

hold down bolts.

setting. Follow procedure as outlined in Section 7.

(e) The outboard bearing for the screw

(d) Check all wiring and connections to make

conveyor may need replacing.

sure they are not broken or bare. Take care to check the

(f) Hardface the screw conveyor. An extra

heavy crossover cable.

hardfaced screw conveyor should be kept in stock. As the

(e) Check the screed plate thickness and look

one on the machine starts to show wear, it should be

for cracks.

replaced and built back up with hardface.

(f) Disassemble the depth control screws and

socket. Clean out and check for wear and excessive

looseness in these sockets, which could cause a wavy mat.

Page 130