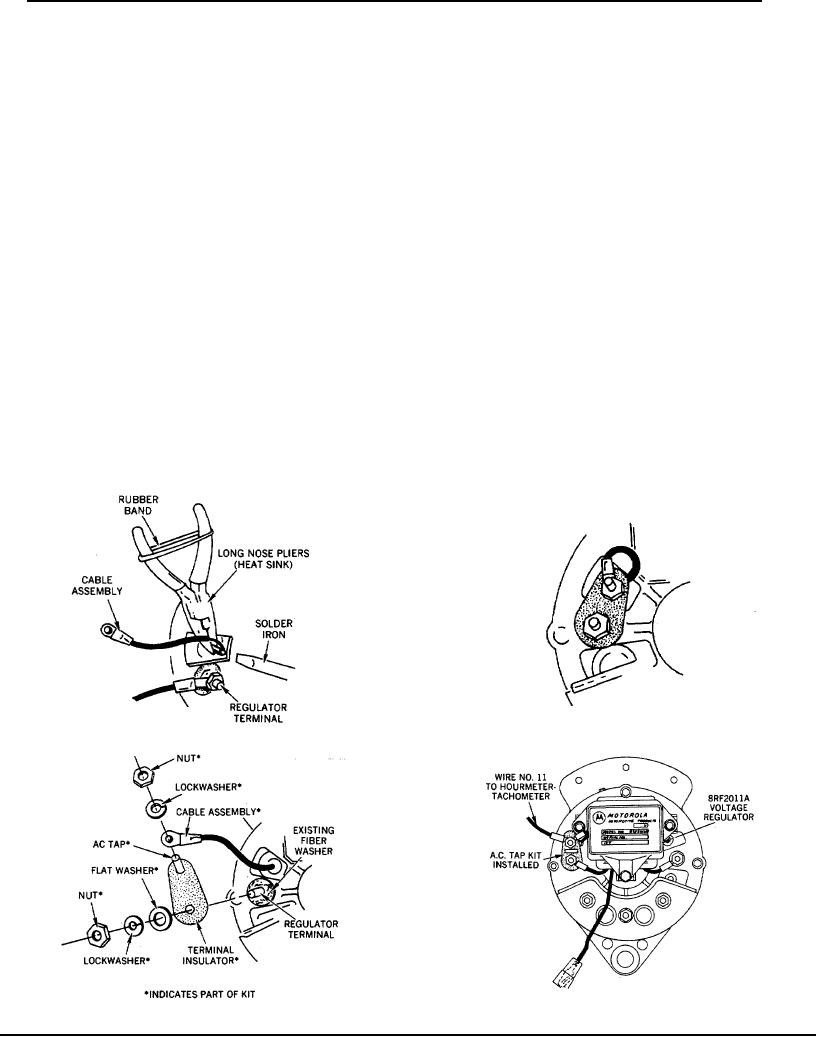

ATTACHMENT OF A.C. TAP TO D.C. GENERATOR

The hourmeter-tachometer on the instrument panel which indicates engine speed and records the

number of hours of engine operation derives its tachometer function from an alternating current (A.C.) tap

on the 12 V.D.C. generator. The A.C. tap must be applied to a diode lead on the 12 V.D.C. generator,

using an effective heat sink to prevent destruction of the diode.

In the event that a new 12 V.D.C. generator is installed, transfer the A.C. tap kit from the old unit to the

new in the following manner.

1.

Form tight loop on stripped end of cable assembly and slip over lead of diode as shown in Figure 14.

2.

Solder-cable assembly to diode lead.

CAUTION

Use long nose pliers as heat sink to prevent damage to diode. (See Figure 14)

3. Remove all nuts and washers (and connectingwires, if generator is already installed) from

insulating fiber washer on terminal.

4. Mount terminal insulator to REGULATOR TERMINAL and secure with nut, lockwasher and flat washer

(supplied in Kit). Align terminal insulator as shown in Figure 16. Reconnect all connecting wires to terminal.

5. Connect terminal of newly soldered cable assembly to A.C.

tap on terminal insulator and secure with

lockwasher and nut provided.

6.

Use keps nut removed from generator on REGULATOR TERMINAL of generator. Leave A.C. tap.

Figure 16

Figure 14

Figure 17

Figure 15

Page 22