Fuel, Oil and Coolant Specifications

DETROIT DIESEL FUEL OIL SPECIFICATIONS

GENERAL CONSIDERATIONS

All diesel engines require heavy-duty lubricating oils. Basic requirements of such oils are:

Lubricating Quality

High Heat Resistance

Control of Contaminants

LUBRICATING QUALITY. The reduction of friction and wear by maintaining an oil film between moving parts is the primary requisite

of a lubricant. Film thickness and its ability to prevent metal-to-metal contact of moving parts is related to oil viscosity. The

optimums for Detroit Diesel engines are SAE 40 or 30 weight.

HIGH HEAT RESISTANCE. Temperature is the most important factor in determining the rate at which deterioration or oxidation of

the lubricating oil will occur. The oil should have adequate thermal stability at elevated temperatures, thereby precluding formation of

harmful carbonaceous and/or ash deposits.

CONTROL OF CONTAMINANTS. The piston and compression rings must ride on a film of oil to minimize wear and prevent cylinder

seizure. At normal rates of consumption, oil reaches a temperature zone at the upper part of the piston where rapid oxidation and

carbonization can 'occur. In addition, as oil circulates through the engine, it is continuously contaminated by soot, acids, and water

originating from combustion. Until they are exhausted, detergent and dispersant additives aid in keeping sludge and varnish from

depositing on engine parts. But such additives in excessive quantities can result in detrimental ash deposits. If abnormal amounts of

insoluble deposits form, particularly on the piston in the compression ring area, early engine failure may result. Oil that is carried up

the cylinder liner wall is normally consumed during engine operation. The oil and additives leave carbonaceous and/or ash deposits

when subjected to the elevated temperatures of the combustion chamber. The amount of deposits is influenced by the oil

composition, additive content, engine temperature. and oil consumption rate.

DETROIT DIESEL LUBRICATING OIL SPECIFICATIONS

OIL QUALITY

OIL QUALITY is the responsibility of the oil supplier. (The term oil supplier is applicable to refiners, blenders, and rebranders of

petroleum products, and does not include distributors of such products.)

There are hundreds of commercial crankcase oils marketed today. Obviously, engine manufacturers or users cannot completely

evaluate the numerous commercial oils. The selection of a suitable lubricant in consultation with a reliable oil supplier, observance of

his oil drain recommendations (based on used oil sample analysis and experience) and proper filter maintenance, will provide the

best assurance of satisfactory oil performance.

Detroit Diesel Allison lubricant recommendations are based on general experience with current lubricants of various types and give

consideration to the commercial lubricants presently available.

RECOMMENDATION

Detroit Diesel engines have given optimum performance and experienced the longest service life with the following oil performance

levels having the ash and zinc limits shown:

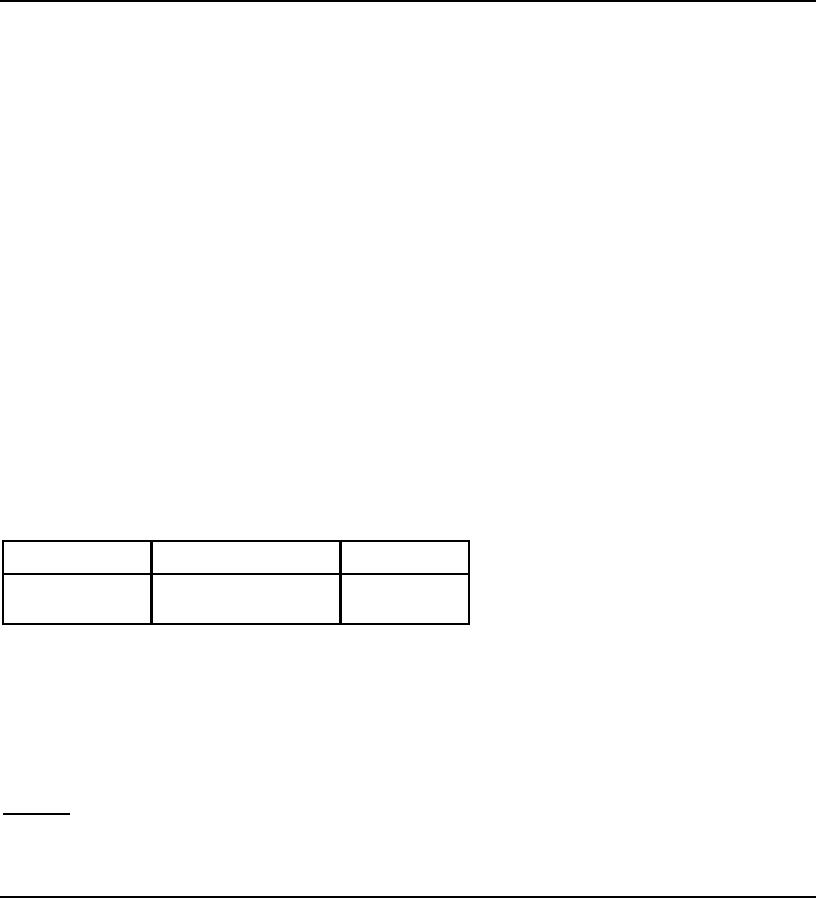

Former Military

API Letter Code

Identification

Service Classification

SAE Grade

40 or 30

MIL-L-

CC/SC

2104B/1964MS *

40 or 30

Supplement 1**

CB

*Military Specification MIL-L-2104B is obsolete and new developed products can no longer be qualified to meet this performance

level. However, many lubricants formulated to meet the performance criteria of MIL-L-2104B/1964MS are still being marketed.

Detroit Diesel engines have given optimum performance and experienced the longest service life using MIL-L-2104B/1964MS

lubricants. The majority of MIL-L-2104B/1964MS lubricants have a sulfated ash content between 0.55 and 0.85 percent by weight.

**Supplement I oils have a history of very satisfactory performance in Detroit Diesel engines. Supplement 1oils have a relatively low

ash content. However, the Supplement I oil specification is obsolete and new products cannot be qualified to meet this performance

level. Some older formulations are still distributed and used by Detroit Diesel engine customers.

SAE 40 grade oil has performed satisfactorily and is recommended in Detroit Diesel engines. Obviously, the expected ambient

temperatures and engine cranking capability must be considered by the engine owner/operator when selecting the proper grade of

oil. Only when the ambient temperatures and engine cranking capabilities result in difficult starting should SAE 30 grade oil be

used.

ASH LIMIT

The sulfated ash (ASTM D-874) limit of all the lubricants recommended or selected as alternates for use in Detroit Diesel engines

shall not exceed 1.000 percent by weight, except lubricants that contain only barium detergent-dispersant salts where 1.500 percent

by weight is allowed. Lubricants having a sulfated ash content between 0.55 and 0.85 percent by weight have a history of excellent

performance in Detroit Diesel engines. Lubricants having a sulfated ash content greater than 0.85 percent by weight are prone to

produce greater deposit levels in the ring belt and exhaust valve areas of the engine.

Page 67