TM 5-3895-385-23-1

0181

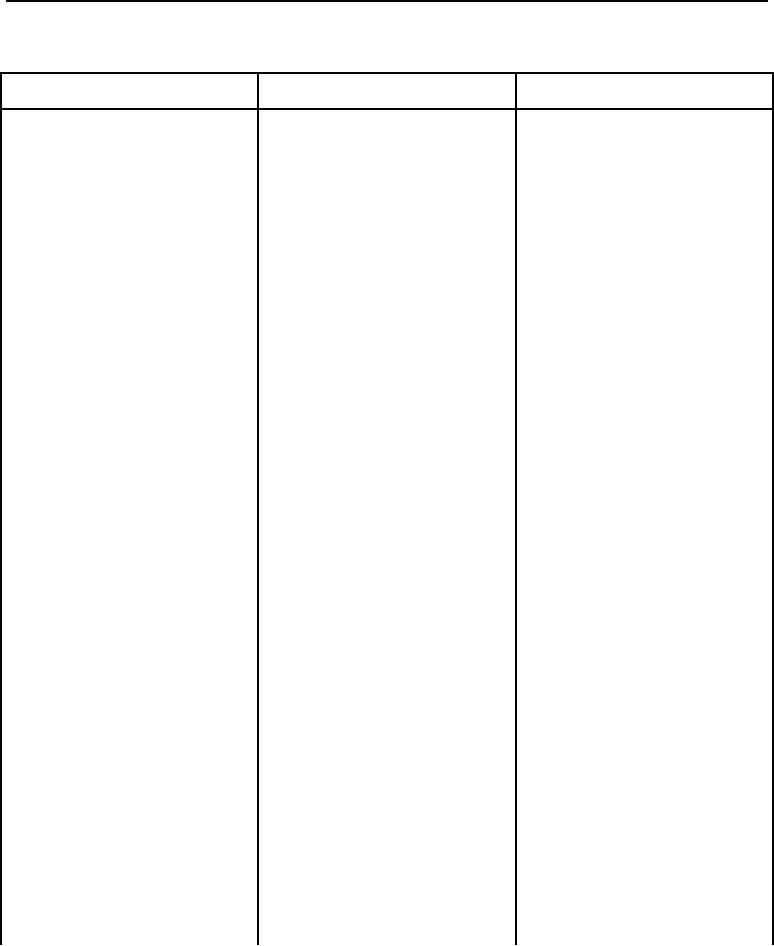

Table 1. Screed Controller Offline Fault Troubleshooting Procedures -- Continued.

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

6. Measure voltage (WP 0443, Vol

1. If voltage reads a minimum of 22

3) between main wiring harness

VDC, turn keyless engine switch

W1 J1 Pin 1 and W1 J1 Pin 50

to the OFF position (TM 5-3895-

(WP 0451, Vol 3, Figure 1).

385-10), and proceed to

malfunction 6.

2. If voltage reads below 22 VDC,

turn keyless engine switch to the

OFF position (TM 5-3895-385-

10), and replace main wiring

harness (WP 0373, Vol 2).

3. Fuse blown.

1. Access fuse box (WP 0277, Vol

2).

2. Measure for continuity (WP

1. If continuity is present, proceed

0443, Vol 3) across screed

to next malfunction.

controller fuse (WP 0447, Vol 3,

Figure 1).

2. If no continuity is present,

replace screed controller fuse

(WP 0277, Vol 2).

4. Main wiring harness has an

1. Measure for continuity (WP

1. If continuity is present, proceed

open circuit.

0443, Vol 3) between main

to next test.

wiring harness W1 J1 Pin 1 and

known good ground (WP 0451,

Vol 3, Figure 1).

2. If no continuity is present,

replace main wiring harness

(WP 0373, Vol 2).

2. Disconnect main wiring harness

W1 J4 from fuse box (WP 0451,

Vol 3, Figure 1).

3. Measure for continuity (WP

1. If continuity is present, proceed

0443, Vol 3) between main

to next malfunction.

wiring harness W1 J1 Pin 50 and

main wiring harness W1 J4 Pin

25 (WP 0451, Vol 3, Figure 1).

2. If no continuity is present,

replace main wiring harness

(WP 0373, Vol 2).

0181-3