TM 5-3895-385-23-1

0088

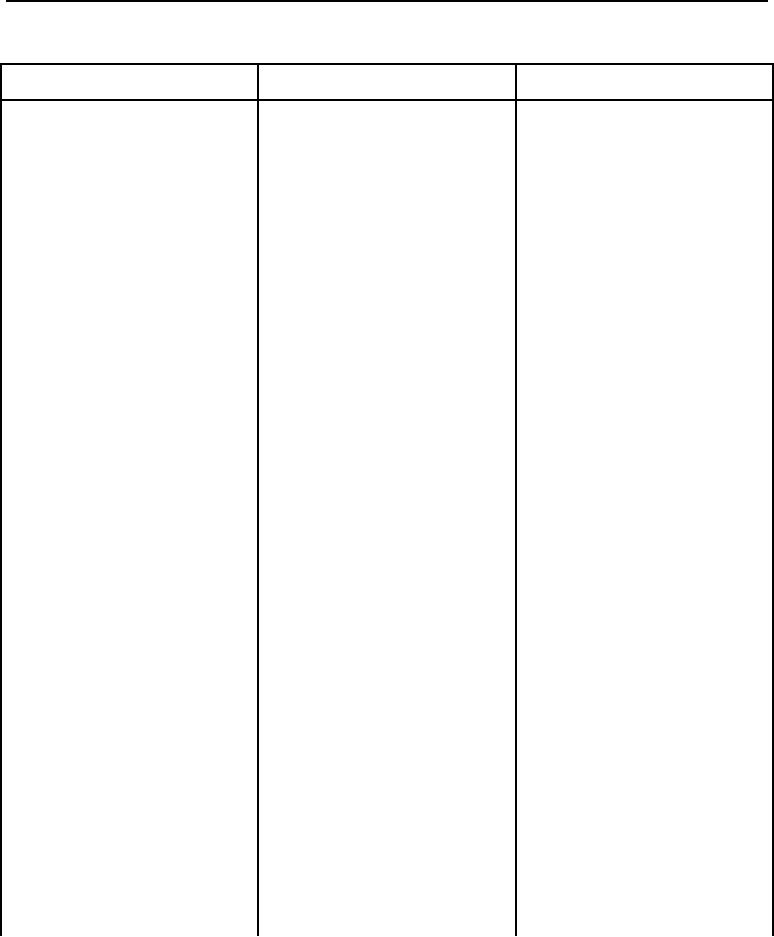

Table 1. Engine Fails to Crank Troubleshooting Procedures -- Continued.

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

3. Check propel controller module

1. If propel controller module ECM

ECM for damage or loose pin.

has damage or loose pin,

replace propel controller module

ECM (WP 0399, Vol 2).

2. If no damage is found, proceed

to next malfunction.

7. Main wiring harness has

Check main wiring harness W1 J2

1. If main wiring harness has

damage or loose pin.

for damage or loose pin (WP 0451,

damage or loose pin, repair or

Vol 3, Figure 2).

replace main wiring harness

(WP 0373, Vol 2).

2. If no damage is found, proceed

to next malfunction.

8. Main wiring harness has an

Measure for continuity (WP 0443,

1. If continuity is present, proceed

open circuit.

Vol 3) between main wiring harness

to next malfunction.

W1 J1 Pin 46 and main wiring

harness W1 J4 Pin 12 (WP 0451,

Vol 3, Figure 3).

2. If no continuity is present,

replace main wiring harness

(WP 0373, Vol 2).

9. Main wiring harness has a short

Measure for continuity (WP 0443,

1. If continuity is present, replace

circuit.

Vol 2) between main wiring harness

main hydraulic manifold wiring

W1 J4 Pin 12 and all other pins on

harness (WP 0373, Vol 2).

the main wiring harness W1 J4 (WP

0451, Vol 3, Figure 3).

2. If no continuity is present,

replace propel controller module

ECM (WP 0399, Vol 2).

10. Main wiring harness has an

Remove left pedestal access panel,

1. If continuity is present, proceed

open circuit.

and measure for continuity (WP

to next malfunction.

0443, Vol 3) between main wiring

harness W1 J11 Pin 4 (WP 0451,

Vol 3, Figure 6) and main wiring

harness W1 J4 Pin 13 (WP 0451,

Vol 3, Figure 3).

2. If no continuity is present,

replace main wiring harness

(WP 0373, Vol 2).

0088-5