TM 5-3895-385-23-1

0055

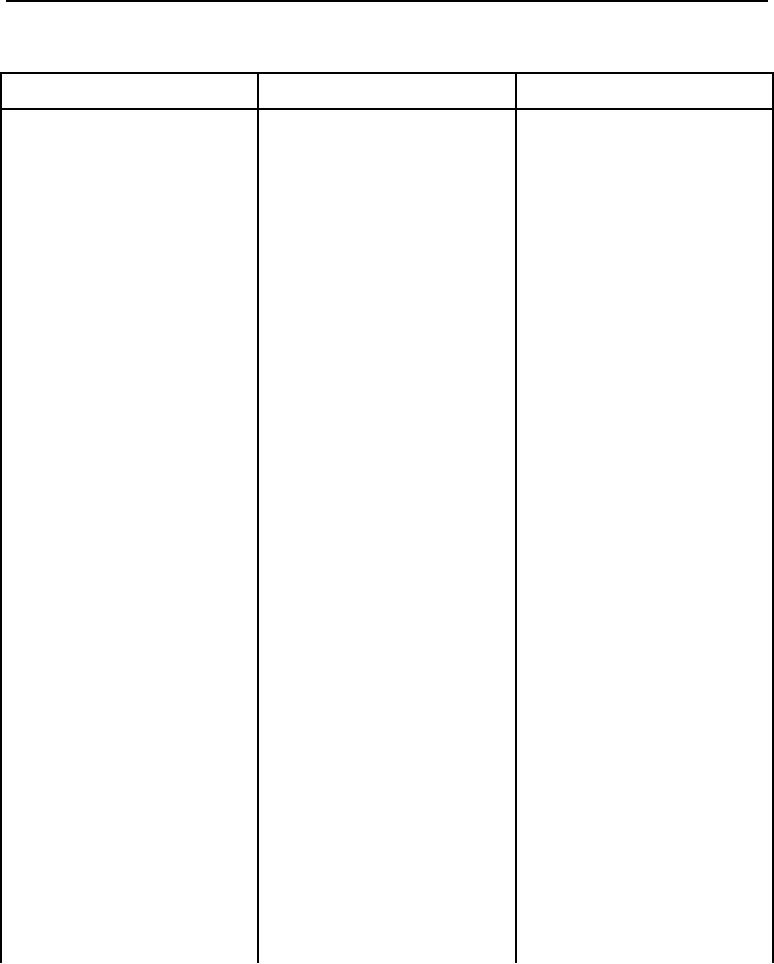

Table 1. SPN#630, FMI#2 ― Severe Loss of Data From ECM -- Continued.

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

2. If battery voltage is not at least

12.4 VDC during engine crank,

turn keyless engine switch to

OFF position (TM 5-3895-385-

10), and replace batteries (WP

0357, Vol 2).

4. Battery connections faulty.

Check battery connections for

1. If tight and corrosion-free,

tightness and corrosion.

proceed to malfunction 6.

2. If loose or corroded, tighten and

clean terminals (WP 0357, Vol

2).

5. Engine interface wiring harness

1. Remove engine interface wiring

fuse fault.

harness 30 amp fuse from the

ECM battery supply positive (+)

line fuse holder (WP 0448, Vol 3,

Figure 20).

2. Inspect 30 amp fuse for damage.

1. If fuse wire is broken, replace

engine interface wiring harness

fuse (WP 0448, Vol 3, Figure

20).

2. If fuse is not damaged, reinsert

fuse into fuse holder, and

proceed to next test.

3. Remove engine interface wiring

harness 5-amp fuse from the

start switch ignition line fuse

holder (WP 0448, Vol 3, Figure

22).

4. Inspect 5-amp fuse for damage.

1. If fuse wire is broken, replace

engine interface wiring harness

fuse (WP 0448, Vol 3, Figure

22).

2. If fuse is not damaged, reinsert

fuse into fuse holder, and

proceed to next malfunction.

6. Engine interface wiring harness

1. Disconnect engine interface

damaged.

wiring harness W16 from all

connection points (WP 0451, Vol

3, Figure 35 and Figure 36).

0055-3