TM 5-3895-385-23-1

0050

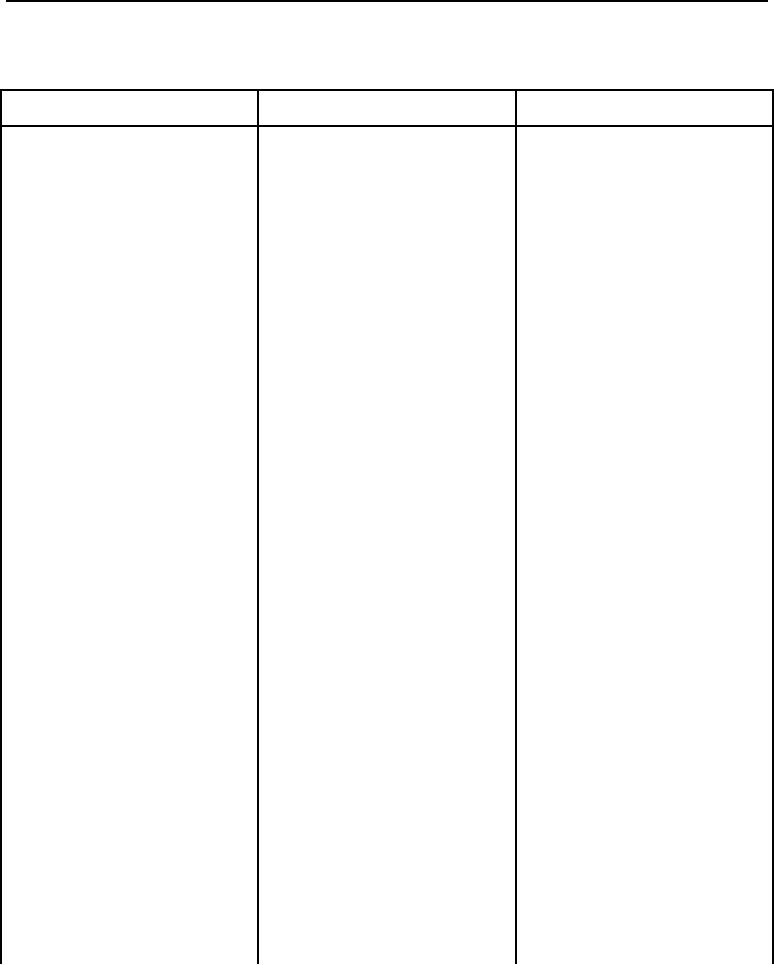

Table 1. SPN#612, FMI#2 ― Signals Reversed On Engine Speed

and Camshaft Position Sensors -- Continued.

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

2. Engine speed sensor is

Inspect engine speed sensor for

1. If damaged, replace engine ECM

damaged.

damage (WP 0334, Vol 2).

speed sensor (WP 0333, Vol 2).

2. If not damaged, proceed to next

malfunction.

3. Engine camshaft position sensor

Inspect engine camshaft position

1. If damaged, replace engine

is damaged.

sensor for damage (WP 0334, Vol

camshaft position sensor (WP

2.

0333, Vol 2).

2. If not damaged, proceed to next

malfunction.

4. Engine ECM harness connectors

1. Disconnect engine ECM wiring

are damaged.

harness connector W25 C11

from engine camshaft position

sensor (WP 0451, Vol 3, Figure

46).

2. Inspect engine ECM wiring

1. If damaged, replace engine ECM

harness connector W25 C11 for

wiring harness W25 (WP 0334,

damage.

Vol 2).

2. If not damaged, restore

equipment to original condition,

and proceed to next test.

3. Disconnect engine ECM wiring

harness connector W25 C12

from engine speed sensor (WP

0451, Vol 3, Figure 46).

4. Inspect engine ECM wiring

1. If damaged, replace engine ECM

harness connector W25 C12 for

wiring harness W25 (WP 0334,

damage.

Vol 2).

2. If not damaged, restore

equipment to original condition,

and proceed to next test.

5. Turn BATTERY DISCONNECT

switch to OFF position (TM 5-

3895-385-10), and wait for 5

seconds.

6. Install fuse box (WP 0277, Vol

2).

0050-2