TM 5-3895-373-34

Table 2-7. Auger/Conveyor System Troubleshooting - Continued.

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

1.

AUGER/CONVEYOR DOES NOT OPERATE OR OPERATES SLUGGISHLY- Continued.

NOTE

In step 2, the auger must be blocked from rotating. This is done to simulate a load so

the affected hydraulic system can build load pressure. If pressure is checked with

auger free, system pressure will not increase to the specified pressure at test ports.

Step 2.

Block rotation of auger, and check system pressure as follows:

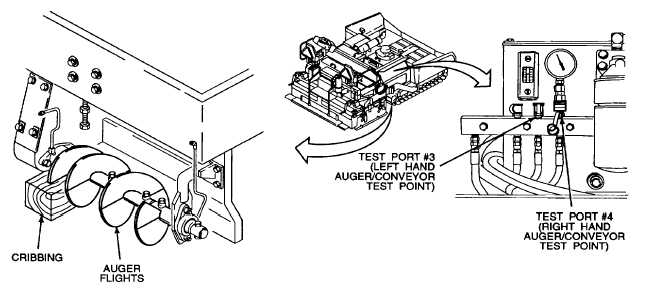

a. Place cribbing beneath inside edge of auger being tested. Cribbing must be positioned to stop

auger rotation.

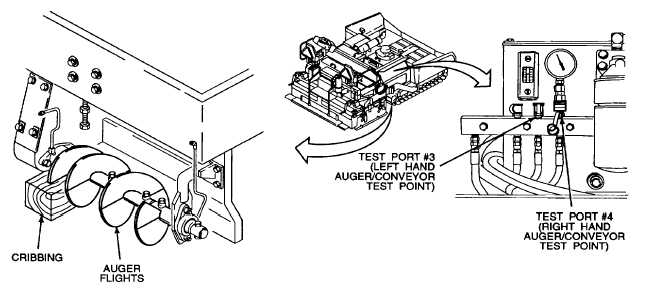

b. Install pressure gauge into test manifold, using test port #3 for left hand auger/conveyor and test

port #4 for right hand auger/conveyor.

CAUTION

Ensure flat part of inside auger flight is against cribbing before setting throttle to MAX.

If auger flight is not against cribbing when throttle is set to MAX, sudden shock may

break auger flight.

c. Start engine and set throttle control switch to MAX. Refer to TM 5-3895-373-10.

d. Open right access door per TM 5-3895-373-10. Remove right access cover per TM 5-3895373-

10. Energize blocked auger until it is stopped against cribbing for a maximum of five seconds.

System pressure should be 2750 psi (28 961 kPa) with engine at 2640 ±50 rpm.

If pressure is not 2750 psi (18 961 kPa), adjust relief pressure on auger/conveyor control relief

valve to 2750 psi (18 961 kPa) when measured at test port, per paragraph 2.51.

2-47